After the busy harvesting season, proper storage of combine harvesters ensures they remain in top condition, ready for the next cycle. Implementing systematic procedures minimizes wear, prevents unexpected breakdowns, and extends the lifespan of these powerful machines.

Cleaning and Inspection Protocols

Before stowing away a combine harvester, thorough cleaning and inspection are essential. Residue from grains, chaff, and debris can promote rust and attract pests, leading to costly repairs.

- Exterior wash: Use high-pressure water to remove dirt and crop residue from the header, grain tank, and engine compartments. Avoid direct jets on electrical connections.

- Undercarriage clearance: Inspect and clear the undercarriage, augers, and reel for compacted material. Residual bits can hinder moving parts and cause corrosion.

- Air filter maintenance: Replace or clean air filters to ensure reliability in the next season. Contaminated filters restrict airflow and raise engine temperatures.

- Inspection of belts and chains: Check for cracks, wear, and proper tension. Lubricate or replace components showing signs of stress to maintain efficiency.

- Electrical system check: Examine wiring harnesses, connectors, and battery terminals. Remove any moisture and apply dielectric grease to prevent future oxidation.

Detailed Inspection Checklist

- Hydraulic lines: Look for leaks or worn fittings.

- Tire or track condition: Verify correct pressure and inspect tread depth.

- Grain tank seals: Ensure there are no gaps or tears that could allow moisture ingress.

- Safety systems: Test lights, alarms, and emergency stops.

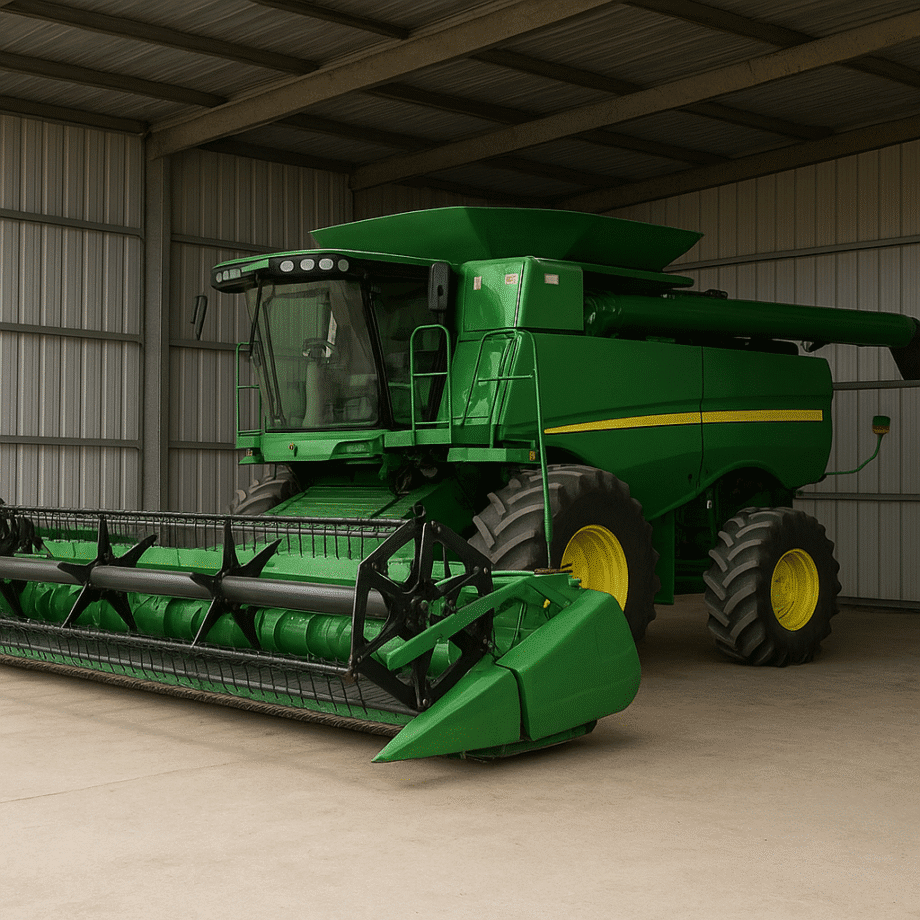

Choosing the Right Storage Environment

Selecting an appropriate storage location directly impacts the performance and longevity of the harvester. Key environmental factors include humidity control, temperature stability, and space accessibility.

- Indoor vs. Outdoor Storage: Whenever possible, store combines in a dry, climate-controlled facility. Outdoor storage requires robust covers and elevated platforms to avoid water pooling.

- Ventilation: Ensure adequate airflow to prevent condensation. Proper ventilation reduces mold growth and rust formation on metal surfaces.

- Flooring and spacing: Store heavy machinery on level, sealed concrete floors. Maintain clearance around each unit for routine checks and air circulation.

- Pest management: Use traps or repellents to keep rodents and insects away from wiring and insulation. Inspect staging areas regularly.

- Security measures: Install locks, cameras, and lighting to deter theft and vandalism during off-season months.

Environmental Controls

- Dehumidifiers: Position units in enclosed storage to manage moisture levels below 50% relative humidity.

- Temperature monitoring: Install sensors to avoid extreme fluctuations that can stress seals, gaskets, and electronic components.

- Air circulation fans: Promote continuous airflow, preventing stagnant areas where moisture might accumulate.

Maintenance and Preservation Procedures

Active maintenance during storage keeps a combine harvester ready for rapid deployment. Preventive actions focus on lubrication, fuel treatment, and protective coatings.

- Lubrication regime: Apply manufacturer-recommended greases to bearings, pivot points, and chains. A minimal lubrication schedule every 30 days prevents metal-on-metal wear.

- Fuel system care: Fill the tank to reduce condensation, then add a fuel stabilizer to prevent varnish and gum buildup. Run the engine for a few minutes to distribute the additive through injectors.

- Oil and filter change: Replace engine oil and filters before storage. Clean oil is less likely to carry contaminants that can corrode internal parts.

- Hydraulic fluid treatment: Check fluid levels and top off with fresh fluid to prevent moisture accumulation in the reservoir.

- Protective coatings: Spray exposed metal surfaces with a corrosion inhibitor. This creates a barrier against humidity and airborne chemicals.

Seasonal Preparation Steps

- Winterization: Drain coolant or use antifreeze formulations tailored to low temperatures.

- Battery maintenance: Disconnect batteries, clean terminals, and store on trickle chargers to maintain optimal voltage.

- Header detachment: If applicable, detach headers and store them separately to relieve stress on mounting points.

Documentation and Operational Readiness

Comprehensive records ensure efficient service scheduling and quick troubleshooting when the next harvest arrives. Accurate logs support warranty claims and assist service technicians in diagnosing issues.

- Service logs: Document cleaning dates, inspection findings, and maintenance tasks performed. Include component serial numbers and hours of operation.

- Parts inventory: Track commonly replaced items such as belts, filters, and seals. Ordering spares early prevents downtime under harvest pressure.

- Operator manuals: Store digital and paper copies in a designated binder or drive. Highlight key sections on cold starts, lubrication points, and emergency procedures.

- Software updates: Ensure onboard computer systems run the latest firmware. Periodic updates can improve performance and introduce diagnostic features.

- Training material: Provide refresher courses for operators focusing on startup protocols, safety checks, and advanced controls.

Checklist Before Deployment

- Review service history and confirm completion of all off-season tasks.

- Test engine start and monitor for unusual noises or warning lights.

- Calibrate sensors, yield monitors, and GPS modules as needed.

- Perform a short field run to verify harvest components operate smoothly.