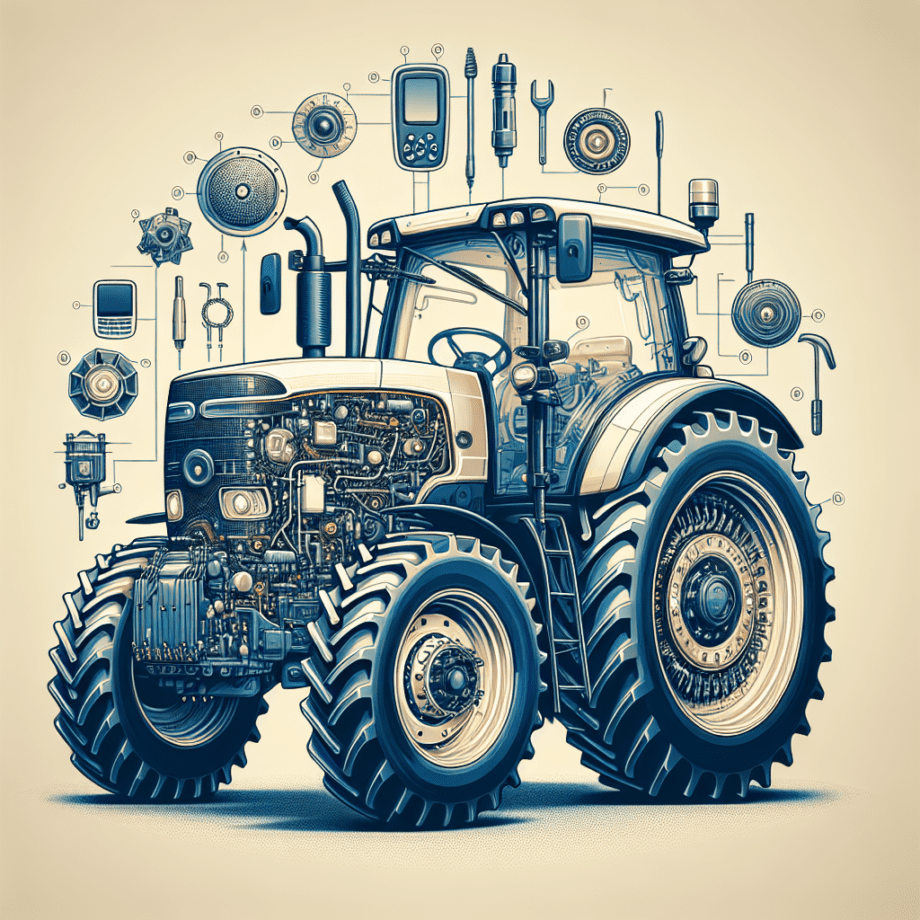

Tractors are indispensable tools in modern agriculture, but like any machinery, they can encounter issues that hinder their performance. Understanding how to troubleshoot common tractor problems can save time, money, and ensure that farming operations run smoothly. This article delves into the most frequent issues faced by tractor owners and provides practical solutions to address them.

Engine Problems

The engine is the heart of any tractor, and when it fails to operate correctly, the entire machine can become useless. Common engine problems include difficulty starting, overheating, and loss of power. Each of these issues can stem from various causes, and understanding them is crucial for effective troubleshooting.

Difficulty Starting

One of the most common complaints among tractor owners is difficulty starting the engine. This issue can be particularly frustrating, especially during critical farming periods. Several factors can contribute to this problem:

- Battery Issues: A dead or weak battery is often the culprit. Ensure the battery is fully charged and the terminals are clean and tightly connected.

- Fuel Problems: Check the fuel level and ensure that the fuel is not contaminated. Old or dirty fuel can clog the fuel system, preventing the engine from starting.

- Ignition System: Inspect the spark plugs, ignition coil, and wiring. Worn-out spark plugs or faulty ignition components can prevent the engine from firing up.

Overheating

Overheating is another common issue that can cause significant damage if not addressed promptly. The primary causes of overheating include:

- Cooling System Failures: Check the radiator, coolant levels, and hoses for leaks or blockages. A malfunctioning water pump can also lead to overheating.

- Thermostat Issues: A stuck thermostat can prevent coolant from circulating properly, causing the engine to overheat.

- Fan Problems: Ensure the cooling fan is working correctly. A broken or malfunctioning fan can reduce airflow, leading to increased engine temperatures.

Loss of Power

A tractor that loses power can be a significant hindrance to farming operations. Common causes of power loss include:

- Fuel System Blockages: Check the fuel filters and lines for blockages. Clean or replace them as necessary to ensure proper fuel flow.

- Air Filter Issues: A clogged air filter can restrict airflow to the engine, reducing its power output. Regularly inspect and clean or replace the air filter.

- Exhaust System Problems: Inspect the exhaust system for blockages or damage. A restricted exhaust can cause backpressure, reducing engine performance.

Hydraulic System Issues

The hydraulic system is essential for operating various attachments and implements on a tractor. When the hydraulic system fails, it can severely limit the tractor’s functionality. Common hydraulic system issues include slow or unresponsive hydraulics, leaks, and unusual noises.

Slow or Unresponsive Hydraulics

When the hydraulic system is slow or unresponsive, it can be challenging to perform tasks efficiently. Possible causes include:

- Low Hydraulic Fluid Levels: Check the hydraulic fluid levels and top up if necessary. Low fluid levels can reduce the system’s efficiency.

- Contaminated Hydraulic Fluid: Dirty or contaminated hydraulic fluid can cause blockages and reduce system performance. Regularly change the hydraulic fluid and filters.

- Worn Hydraulic Pump: A worn or damaged hydraulic pump can reduce the system’s pressure and flow. Inspect the pump and replace it if necessary.

Hydraulic Leaks

Hydraulic leaks can lead to reduced system performance and potential damage to other components. Common sources of leaks include:

- Damaged Hoses and Fittings: Inspect all hoses and fittings for signs of wear, cracks, or damage. Replace any faulty components to prevent leaks.

- Seal Failures: Check the seals on hydraulic cylinders and other components. Worn or damaged seals can cause leaks and should be replaced promptly.

- Loose Connections: Ensure all hydraulic connections are tight and secure. Loose connections can lead to leaks and reduced system performance.

Unusual Noises

Unusual noises from the hydraulic system can indicate underlying issues that need attention. Common causes of unusual noises include:

- Air in the System: Air trapped in the hydraulic system can cause noise and reduce performance. Bleed the system to remove any air pockets.

- Worn Components: Inspect the hydraulic pump, valves, and cylinders for signs of wear or damage. Replace any worn components to prevent further issues.

- Contaminated Fluid: Dirty or contaminated hydraulic fluid can cause noise and reduce system efficiency. Regularly change the fluid and filters to maintain optimal performance.

Electrical System Failures

The electrical system in a tractor is responsible for powering various components, including lights, sensors, and the ignition system. Electrical system failures can lead to a range of issues, from non-functional lights to a complete inability to start the tractor.

Non-Functional Lights

Non-functional lights can be a safety hazard, especially when operating the tractor in low-light conditions. Common causes of non-functional lights include:

- Blown Fuses: Check the fuse box for any blown fuses and replace them as necessary.

- Faulty Bulbs: Inspect the light bulbs and replace any that are burnt out or damaged.

- Wiring Issues: Check the wiring for any signs of damage or loose connections. Repair or replace any faulty wiring to restore functionality.

Starting Problems

Electrical issues can also prevent the tractor from starting. Common causes include:

- Battery Problems: Ensure the battery is fully charged and the terminals are clean and secure. Replace the battery if it is old or damaged.

- Starter Motor Issues: Inspect the starter motor for signs of wear or damage. Replace the starter motor if it is not functioning correctly.

- Ignition Switch Problems: Check the ignition switch for any signs of wear or damage. Replace the switch if it is not working properly.

Sensor Failures

Modern tractors are equipped with various sensors that monitor different systems and provide crucial information to the operator. Sensor failures can lead to incorrect readings and potential damage to the tractor. Common causes of sensor failures include:

- Dirty or Damaged Sensors: Inspect the sensors for any signs of dirt or damage. Clean or replace the sensors as necessary to ensure accurate readings.

- Wiring Issues: Check the wiring connected to the sensors for any signs of damage or loose connections. Repair or replace any faulty wiring to restore proper sensor function.

- Software Issues: Ensure the tractor’s software is up to date. Outdated software can cause sensor malfunctions and incorrect readings.

Transmission Problems

The transmission system in a tractor is responsible for transferring power from the engine to the wheels. Transmission problems can lead to a range of issues, from difficulty shifting gears to complete transmission failure.

Difficulty Shifting Gears

Difficulty shifting gears can be a significant hindrance to tractor operation. Common causes include:

- Low Transmission Fluid: Check the transmission fluid levels and top up if necessary. Low fluid levels can make it difficult to shift gears.

- Worn Clutch: Inspect the clutch for signs of wear or damage. Replace the clutch if it is not functioning correctly.

- Linkage Issues: Check the gear linkage for any signs of damage or misalignment. Repair or replace any faulty components to restore proper gear shifting.

Transmission Slipping

Transmission slipping can cause a loss of power and make it difficult to operate the tractor effectively. Common causes include:

- Worn Transmission Bands: Inspect the transmission bands for signs of wear or damage. Replace the bands if they are not functioning correctly.

- Low Transmission Fluid: Check the transmission fluid levels and top up if necessary. Low fluid levels can cause the transmission to slip.

- Internal Damage: Inspect the transmission for any signs of internal damage. Repair or replace any faulty components to restore proper transmission function.

Unusual Noises

Unusual noises from the transmission can indicate underlying issues that need attention. Common causes of unusual noises include:

- Worn Gears: Inspect the gears for signs of wear or damage. Replace any worn gears to prevent further issues.

- Low Transmission Fluid: Check the transmission fluid levels and top up if necessary. Low fluid levels can cause unusual noises.

- Damaged Bearings: Inspect the bearings for signs of wear or damage. Replace any faulty bearings to restore proper transmission function.

Conclusion

Understanding how to troubleshoot common tractor problems is essential for maintaining the efficiency and longevity of your agricultural machinery. By addressing issues promptly and performing regular maintenance, you can ensure that your tractor remains in optimal working condition. Whether it’s engine problems, hydraulic system issues, electrical system failures, or transmission problems, having the knowledge and tools to troubleshoot and resolve these issues can save time, money, and prevent unnecessary downtime in your farming operations.