Post-harvest machinery plays a crucial role in the agricultural industry by ensuring that crops are efficiently handled and stored after they are harvested. This article delves into the various types of post-harvest machinery, their functions, and the benefits they offer to farmers and the agricultural sector as a whole.

Types of Post-Harvest Machinery

Post-harvest machinery encompasses a wide range of equipment designed to handle, process, and store crops after they have been harvested. These machines are essential for maintaining the quality and safety of agricultural products. Below are some of the most common types of post-harvest machinery:

Threshers

Threshers are machines used to separate grains from their stalks and husks. This process is vital for crops such as wheat, rice, and barley. Threshers can be operated manually or powered by engines, and they come in various sizes to accommodate different scales of farming operations. The efficiency of threshers significantly reduces the labor required for grain separation, thereby increasing productivity.

Combine Harvesters

Combine harvesters are versatile machines that combine three separate harvesting operations—reaping, threshing, and winnowing—into a single process. These machines are highly efficient and can handle large volumes of crops, making them ideal for large-scale farming. Combine harvesters are equipped with advanced technology to ensure minimal crop loss and maximum yield.

Dryers

Dryers are essential for reducing the moisture content of harvested crops to prevent spoilage and ensure long-term storage. There are various types of dryers, including batch dryers, continuous flow dryers, and solar dryers. Each type has its advantages and is suitable for different types of crops and farming conditions. Proper drying is crucial for maintaining the quality and market value of agricultural products.

Grain Cleaners

Grain cleaners are used to remove impurities such as dirt, stones, and other foreign materials from harvested grains. This process is important for ensuring the quality and safety of the final product. Grain cleaners come in different forms, including air screen cleaners, gravity separators, and rotary cleaners. The choice of grain cleaner depends on the type of crop and the level of cleanliness required.

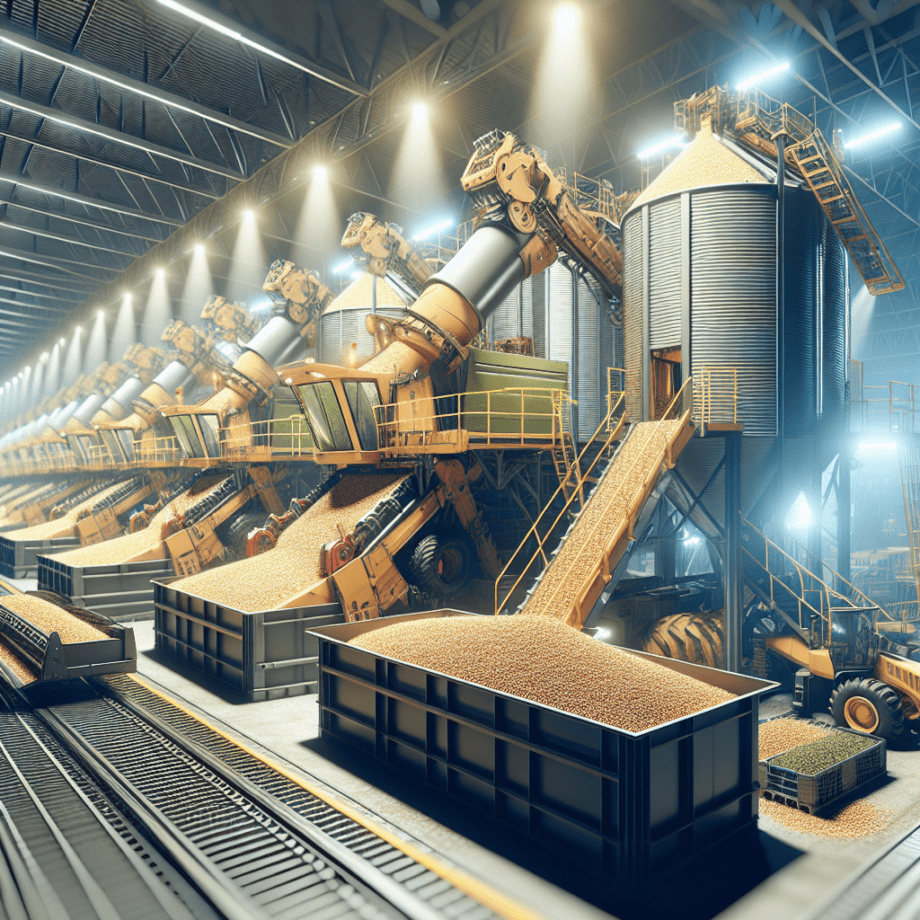

Storage Bins and Silos

Storage bins and silos are used to store harvested crops in bulk. These structures are designed to protect crops from pests, moisture, and other environmental factors that can cause spoilage. Modern storage solutions are equipped with temperature and humidity control systems to ensure optimal storage conditions. Proper storage is essential for maintaining the quality and marketability of agricultural products.

Benefits of Post-Harvest Machinery

The use of post-harvest machinery offers numerous benefits to farmers and the agricultural industry. These benefits include increased efficiency, reduced labor costs, improved crop quality, and enhanced food security. Below are some of the key advantages of using post-harvest machinery:

Increased Efficiency

Post-harvest machinery significantly increases the efficiency of handling and processing crops. Machines such as combine harvesters and threshers can process large volumes of crops in a short amount of time, reducing the need for manual labor and speeding up the overall harvesting process. This increased efficiency allows farmers to manage larger areas of land and produce more crops.

Reduced Labor Costs

The use of post-harvest machinery reduces the reliance on manual labor, which can be costly and time-consuming. By automating various post-harvest processes, farmers can save on labor costs and allocate their resources more effectively. This cost savings can be reinvested into other areas of the farm, such as purchasing new equipment or improving infrastructure.

Improved Crop Quality

Post-harvest machinery helps maintain the quality of crops by minimizing damage and reducing the risk of spoilage. For example, dryers ensure that crops are properly dried to prevent mold growth, while grain cleaners remove impurities that can affect the quality of the final product. By preserving the quality of crops, farmers can achieve higher market prices and increase their profitability.

Enhanced Food Security

Efficient post-harvest handling and storage are essential for ensuring food security. By reducing post-harvest losses and maintaining the quality of crops, post-harvest machinery helps ensure a stable supply of food. This is particularly important in regions where food scarcity is a concern. Proper storage solutions also allow farmers to store surplus crops for future use, providing a buffer against food shortages.

Conclusion

Post-harvest machinery is an indispensable component of modern agriculture. By streamlining the handling, processing, and storage of crops, these machines contribute to increased efficiency, reduced labor costs, improved crop quality, and enhanced food security. As the agricultural industry continues to evolve, the adoption of advanced post-harvest machinery will play a critical role in meeting the growing demand for food and ensuring the sustainability of farming operations.