The efficiency and longevity of agricultural machinery largely depend on the integrity of its hydraulic system. Properly checking hydraulic fluid levels is not just a routine task but a critical component of overall equipment maintenance. Neglecting this vital procedure can lead to equipment downtime, costly repairs, and potential safety hazards. This guide explores best practices for accurately assessing hydraulic fluid levels, identifying common issues, and ensuring peak performance season after season.

Importance of Hydraulic Fluid Levels in Agricultural Machinery

Hydraulic systems power a wide array of implements such as loaders, balers, plows, and harvesters. These systems rely on the right volume and quality of fluid to transmit force, lubricate moving parts, and regulate temperature. Running a machine with insufficient fluid can cause cavitation, overheating, and abrasive wear. Conversely, overfilling may lead to excessive pressure, seal failure, and fluid foaming.

Key reasons for maintaining correct fluid levels include:

- Safe and effective power transmission under heavy load.

- Proper heat dissipation to avoid thermal breakdown.

- Protection against internal corrosion and rust.

- Optimized pump and valve performance for consistent operation.

In challenging field conditions—dusty environments, fluctuating temperatures, and prolonged continuous use—fluid levels can fluctuate. Frequent checks safeguard against unexpected breakdowns, thereby maximizing machine uptime and farm productivity.

Routine Inspection: Preparing for the Check

Before beginning any hydraulic fluid level inspection, ensure you have the following tools and materials:

- A clean, lint-free cloth or rag to wipe the dipstick or sight glass.

- The manufacturer’s specification manual for correct fluid type and capacity.

- A calibrated dipstick or built-in sight gauge marked with maximum and minimum levels.

- Personal protective equipment (PPE): gloves and safety glasses.

Adhering to these preparatory steps promotes an accurate reading and reduces the risk of contamination:

- Park on level ground and engage the parking brake.

- Shut off the engine and allow the system to stabilize for 5–10 minutes.

- Clean around filler caps, sight glasses, and dipsticks to prevent dirt ingress.

Never check fluid levels while the system is under pressure or the engine is running. Doing so may give false readings and introduce air into the system.

Step-by-Step Guide to Checking Hydraulic Fluid Levels

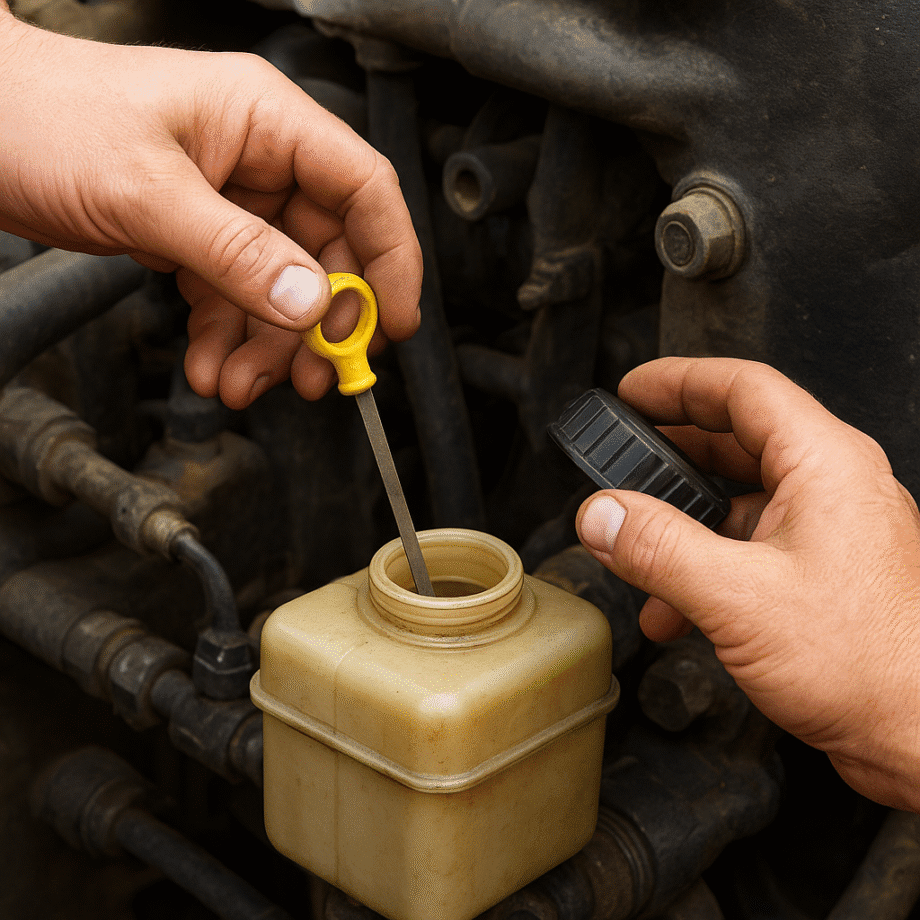

1. Using a Dipstick

Many tractors and implements include a dipstick similar to those in engines:

- Remove the dipstick and wipe it clean with the rag.

- Reinsert it fully, then withdraw to read the fluid mark.

- Ensure the fluid falls between the min and max indicators.

- If the level is low, slowly add the recommended fluid until it reaches the correct mark.

2. Checking a Sight Glass

Sight glasses offer a quick visual method:

- Locate the transparent window on the reservoir body.

- Observe the fluid level relative to etched lines.

- Top up carefully if below the lower line; avoid overfilling past the upper line.

3. Remote Reservoirs and Electronic Sensors

Newer machinery may use remote reservoirs with electronic sensors that trigger dashboard warnings. Always:

- Consult diagnostic codes in the equipment manual.

- Use OEM-approved diagnostic tools for accurate readings.

- Reset sensor alerts after addressing the fluid level.

Regularly monitor sensor data to detect gradual fluid loss due to leaks or internal consumption.

Identifying and Resolving Common Issues

Even with proper checks, issues may arise. Below are typical problems and corrective actions:

Fluid Contamination

- Water or particulate ingress can degrade lubricant properties.

- Use a hydrometer to test for moisture levels above manufacturer limits.

- Replace fluid and inline filters if contamination is detected.

Abrasion and Wear

- Metallic particles from worn components accelerate valve and pump damage.

- Inspect reservoir filters and magnetic plugs; clean regularly.

- Schedule routine oil analysis to track wear debris trends.

Seal Failures and Leaks

- Leaking hoses or fittings lead to fluid loss and drop in pressure.

- Check all seals, O-rings, and connectors for cracks or hardening.

- Replace defective parts using correct sealing compounds and torque specs.

Best Practices for Hydraulic System Maintenance

Consistency in maintenance extends component life and prevents unexpected failures:

- Implement a documented inspection schedule, recording fluid levels and any adjustments.

- Maintain detailed service logs including fluid batch numbers and change dates.

- Use only OEM or equivalent certified hydraulic fluids to preserve warranty and performance.

- Monitor operating temperature—install thermal sensors or heat gauges where possible.

Temperature extremes, whether high or low, can alter fluid viscosity and impact system calibration. In cold climates, consider fluids with improved low-temperature flow characteristics.

Advanced Tips and Troubleshooting Techniques

For complex operations, advanced diagnostics ensure uninterrupted workflow:

- Install inline pressure gauges at critical circuit points to detect blockages or imbalances.

- Use vibration analysis tools to spot early-stage pump wear.

- Adopt remote monitoring solutions connecting machinery health data to a central dashboard.

Integrating predictive maintenance software can analyze trends and forecast service intervals, reducing downtime and repair expenses.

Regular attention to hydraulic fluid levels and system health not only safeguards your investment in agricultural machinery but also boosts field productivity during peak seasons. By following the methods outlined above, you can ensure reliable, efficient, and safe operation of your key hydraulic-driven equipment.