Agricultural machines are the backbone of modern farming, ensuring that planting, harvesting, and soil management are carried out with maximum effectiveness. At the heart of every tractor, combine harvester, and tillage implement lies a network of moving parts that depend on precise lubrication to reduce friction and maintain peak functionality. From the gearbox that transfers power to the blades that cut through stalks, proper use of high-quality oils and greases is essential to extend the residual life of key components and support uninterrupted farm operations.

Fundamentals of Lubrication in Agricultural Machinery

Friction and Wear Control

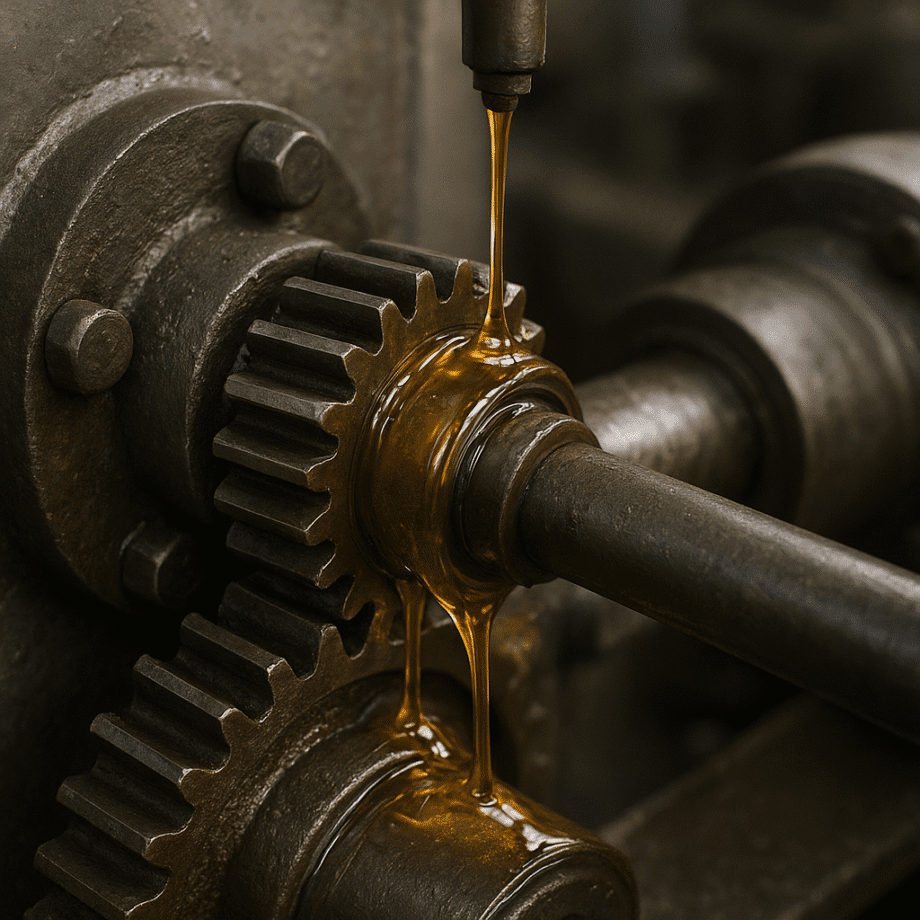

Every time metal surfaces interact under load, friction generates heat and abrasive wear. Over time, this leads to pitting, scoring, and eventual component failure. Effective lubrication forms a thin film between surfaces, preventing direct contact and significantly reducing metal-to-metal abrasion. Key elements include:

- Hydrodynamic film formation

- Boundary lubrication under extreme pressure

- Corrosion inhibition to protect bare metal

Viscosity and Temperature Management

Viscosity measures fluid resistance to flow. In colder climates, a low-viscosity oil ensures swift circulation at start-up, while high-viscosity grades maintain a protective film under heavy loads and high temperatures. Adjusting lubricant grade to seasonal changes prevents oil thinning or breakdown, which can compromise reliability and accelerate wear.

Types of Lubricants

Selecting the right lubricant depends on application demands, load conditions, and operating environment. Common categories include:

- Mineral oils – cost-effective option for general applications

- Synthetic oils – superior stability at wide temperature ranges

- Greases – ideal for sealed bearings and pivot points

- Bio-based lubricants – environmentally sustainable with improved biodegradability

Impact of Lubricants on Performance and Durability

Gearbox Efficiency

The transmission gearbox is a mechanical hub where high torque and variable speeds create intense surface pressures. Using a high-quality, EP (extreme pressure) oil minimizes gear wear and reduces heat generation. Field studies have shown that optimal lubrication can improve power transfer efficiency by up to 15%, cutting fuel consumption and enhancing overall machine performance.

Hydraulic System Longevity

Hydraulics power critical functions such as steering, loader arms, and hydraulic attachments. Contaminants or moisture in hydraulic oil can lead to pump cavitation, valve sticking, and cylinder scoring. Regular fluid analysis and filtration maintain a clean, constant-pressure medium, safeguarding against premature breakdown and costly downtime.

Bearing and Joint Protection

Rolling-element bearings and universal joints are susceptible to fatigue when lubrication fails. Proper grease selection extends service intervals and prevents metal fatigue. In practice, greases with excellent water resistance and anti-oxidation additives offer the best protection in muddy and wet field conditions.

Best Practices for Field Lubrication Management

Scheduled Maintenance Intervals

Adhering to a rigorous lubrication schedule is vital. Operators should:

- Consult OEM guidelines for oil-change intervals

- Monitor in-service hours to time grease replenishment

- Use color-coded pails or tags to avoid cross-contamination

On-Site Oil Analysis

Taking periodic oil samples for laboratory testing provides insight into:

- Particle count and wear metal concentration

- Viscosity shift indicating oxidation or contamination

- Presence of coolant or fuel in lubricants

Early detection of anomalies allows for corrective action before catastrophic failure.

Proper Storage and Handling

Maintaining lubricant quality begins in the storage area. Best practices include:

- Keeping drums sealed and elevated to prevent water ingress

- Labeling containers with batch numbers and open dates

- Using dedicated pumps and dispensing equipment to reduce contamination

Emerging Trends and Sustainable Solutions

Environmentally Friendly Lubricants

With growing emphasis on sustainability, bio-based and biodegradable lubricants are gaining traction. Derived from vegetable oils or synthetic esters, these fluids offer:

- Reduced ecological impact in case of leaks

- Comparable lubrication performance to mineral oils

- Improved worker safety due to lower toxicity

Advanced Additive Technologies

Additive packages tailored for agricultural equipment now incorporate:

- Friction modifiers for lower energy losses

- Anti-wear agents that form protective surface films

- Corrosion inhibitors suited for high-moisture environments

These innovations help machines run longer between service intervals and reduce lifecycle costs.

Condition Monitoring and IoT Integration

Modern tractors and combines can be equipped with onboard sensors to track lubricant condition in real time. Data analytics platforms interpret trends in temperature, pressure, and particle counts to:

- Trigger maintenance alerts before failures occur

- Optimize oil-change schedules based on actual machine usage

- Enhance overall maintenance planning for fleet managers

Maximizing Uptime Through Proactive Lubrication

Operator Training and Awareness

Empowering farm personnel with knowledge about lubrication best practices fosters a culture of care. Training modules should cover:

- Identification of lubricant types and their applications

- Proper grease-gun techniques to avoid over- or under-lubrication

- Visual inspection of seals, gaskets, and lubrication points

Inventory Management

Maintaining an organized lubricant inventory reduces response time for critical repairs. A well-managed system includes:

- Stock levels aligned with seasonal demands

- FIFO (First In, First Out) rotation to prevent oil degradation

- Digital logs to track consumption rates and reorder thresholds

Conclusion of Practices

Through strategic selection of high-performance oils, vigilant condition monitoring, and adoption of sustainable solutions, agricultural machinery can achieve extended service life and improved operational efficiency. Proper lubrication is not just a maintenance task—it is a core component of ensuring that every harvest season proceeds without unexpected breakdowns, guaranteeing both productivity and profitability for today’s farmers.