Agricultural machinery depends on advanced fluid power technologies to perform heavy-duty tasks with precision and reliability. Hydraulic and pneumatic systems each offer unique strengths, catering to a variety of functions on the farm—from powering the lift arms of a tractor to controlling seed drills and sprayer nozzles. Understanding how these systems differ in terms of performance, maintenance, and environmental impact is essential for farmers, equipment manufacturers, and service technicians.

Fundamentals of Hydraulic and Pneumatic Systems

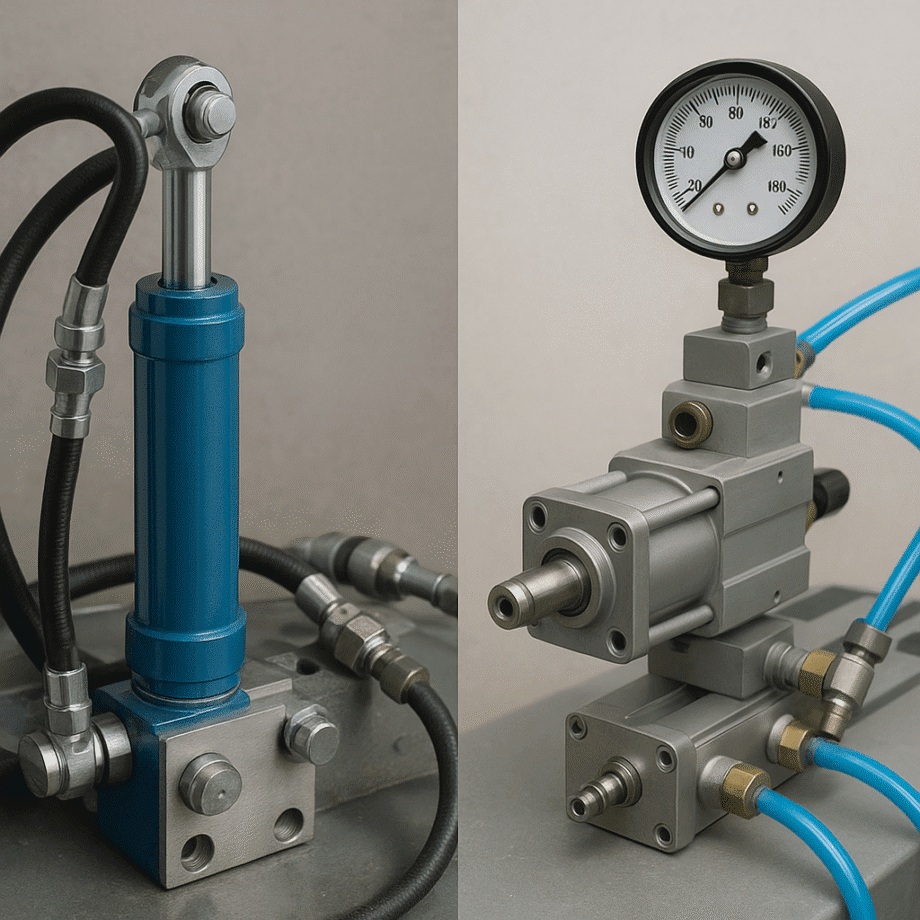

At their core, both systems transmit energy through a medium. Hydraulic technology uses a fluid—typically oil—confined within a circuit, while pneumatic setups rely on air under pressure. The basic components include a source (pump or compressor), control valves, actuators (cylinders or motors), filters, reservoirs, and various fittings. Despite sharing similar architectures, the physical properties of liquids and gases lead to distinct operating characteristics.

Key Components and Operation

- Fluid Reservoir vs. Air Tank: Hydraulics store oil in a reservoir; pneumatics accumulate compressed air in a receiver.

- Pump vs. Compressor: Hydraulic systems employ a positive-displacement pump, whereas pneumatic systems use pistons or rotary screw compressors.

- Actuators: Hydraulic cylinders generate high force for heavy implements, while pneumatic cylinders provide faster linear motion with lower loads.

- Valves and Controls: Directional, pressure, and flow-control valves regulate system behavior. In hydraulics, precise metering valves manage flow rates accurately; in pneumatics, quick-response pilot valves enable rapid cycling.

Physical Principles

Hydraulic fluids are incompressible, transmitting force almost instantly and providing high torque and lifting capacity. In contrast, air is compressible: it acts like a spring, absorbing shocks but reducing positional accuracy. Temperature variations also affect each medium differently—cold climates can thicken hydraulic oil, while extreme heat can degrade seals.

Advantages of Hydraulic Systems

Hydraulics excel in demanding agricultural applications requiring significant power and controlled motion. Their intrinsic properties confer several benefits:

- High Force Density: Hydraulics can generate enormous forces in compact components, ideal for heavy tillage, loader arms, and baler presses.

- Precise Control: Fine adjustment of pressure and flow allows accurate speed and position control, crucial for seed placement and variable-rate spraying.

- Smooth Performance: Incompressibility of oil minimizes vibration and offers steady actuation, improving operator comfort and reducing wear.

- Load Holding: Hydraulic locks maintain cylinder position without energy consumption, ensuring implements remain stable under heavy loads.

- Durability: Properly maintained hydraulic components withstand harsh agricultural environments, resisting dust and moisture.

Typical Applications

Hydraulic systems power the majority of tractor implements: front-end loaders, three-point linkages, backhoes, and supplement OEM attachments like post-hole diggers and snowplows. Their ability to handle shock loads and varied travel speeds makes them indispensable for multi-function machinery.

Advantages of Pneumatic Systems

Pneumatic power offers a contrasting set of strengths, making it suitable for specific tasks in agriculture:

- Speed: Compressed air can extend and retract cylinders rapidly, facilitating quick tool changes or repetitive motions in machinery such as packers or pneumatic seed drills.

- Cleanliness: Air systems pose no contamination risk to crops or soil if leaks occur, unlike oil leaks that can leave residues.

- Cost-Effectiveness: Components are generally less expensive and simpler to install. Compressors require minimal infrastructure compared to complex hydraulic power units.

- Safety: Compressed air systems are less likely to catch fire under high temperatures; any leaked air disperses harmlessly.

- Maintenance: Routine checks involve filter changes and moisture removal; there is no need for oil sampling or fluid analysis.

Specialized Uses

Pneumatics find roles in grain handling (vacuum conveyors and air-blast cleaners), orchard sprayers (air-assisted atomization), and seed metering systems. Their rapid cycling capability enhances throughput during high-speed planting and harvesting operations.

Comparative Analysis in Agricultural Machinery

Choosing between hydraulic and pneumatic solutions involves evaluating operational requirements, cost constraints, and environmental factors. Here are key considerations:

- Load and Force: For implements demanding high torque and sustained force, hydraulics typically outperform pneumatics.

- Precision vs. Speed: Pneumatic devices excel in fast, repetitive tasks, whereas hydraulics deliver superior precision and controllable deceleration.

- Energy Efficiency: Hydraulic systems often operate at higher efficiencies under load. Pneumatics may incur energy losses due to heat and moisture in compressed air.

- Noise Levels: Compressors and exhaust air can generate significant noise, whereas hydraulic pumps, with proper mufflers, run more quietly.

- Portability: Pneumatic tools and attachments are lighter and easier to transport, beneficial for remote or small-scale operations.

Maintenance and Environmental Impact

Effective upkeep and attention to ecological concerns extend equipment lifespan and compliance with regulations. Both systems demand preventive maintenance, but their approaches differ:

- Hydraulic Maintenance: Regular inspection of hoses, seals, and reservoirs for leaks; fluid analysis to detect wear metals and contaminants; replacement of filters and adherence to recommended service intervals.

- Pneumatic Maintenance: Draining moisture traps, inspecting air lines for leaks, ensuring compressor valves operate correctly, and replacing filters to prevent particulate ingress.

Environmental Considerations

Hydraulic oil spills pose pollution risks to soil and waterways, necessitating containment and proper disposal. Biodegradable fluids reduce impact but may compromise performance. Pneumatics, while cleaner, consume significant electrical energy for air compression—optimizing compressor duty cycles and using efficient motors mitigates carbon footprint.

Emerging Trends and Innovations

Advancements in both fields aim to enhance sustainability, reliability, and integration with precision agriculture systems:

- Electro-Hydrostatic Drives: Combine electric motors with hydraulic pumps directly at the wheel hub, improving system modularity and energy recovery during braking.

- Smart Control Valves: Electronic feedback and proportional solenoids enable adaptive flow control based on real-time sensor data, optimizing performance under varying loads.

- Hybrid Pneumatic-Hydraulic Systems: Leverage the speed of pneumatics for rapid positioning and the force of hydraulics for heavy lifting in the same implement.

- Advanced Filtration: Nanofiber filters for hydraulic oil and coalescing filters for air systems enhance contamination control, extending component life.

- Internet of Things (IoT): Predictive maintenance platforms monitor pressure, temperature, and vibration levels, alerting operators before failures occur.

Selecting the right power medium for agricultural machinery involves balancing performance, cost, and environmental impact. By understanding the unique characteristics of hydraulic and pneumatic systems, stakeholders can design, operate, and maintain equipment that maximizes productivity and sustainability across diverse farming operations.