Agricultural machinery has undergone a remarkable transformation, driven by breakthroughs in AI-controlled systems and advanced mechanical engineering. From the early days of simple plows to today’s sophisticated self-driving tractors, each innovation has aimed to boost efficiency, increase crop yield, and promote sustainability. As global demand for food rises, farming operations are under pressure to do more with less—less water, less land, and fewer labor hours. This article explores the future landscape of harvesting robots, the role of precision agriculture, the economic implications of adopting cutting-edge equipment, and the environmental benefits of smarter, resource-conscious farming.

Technological Innovations in Modern Farm Equipment

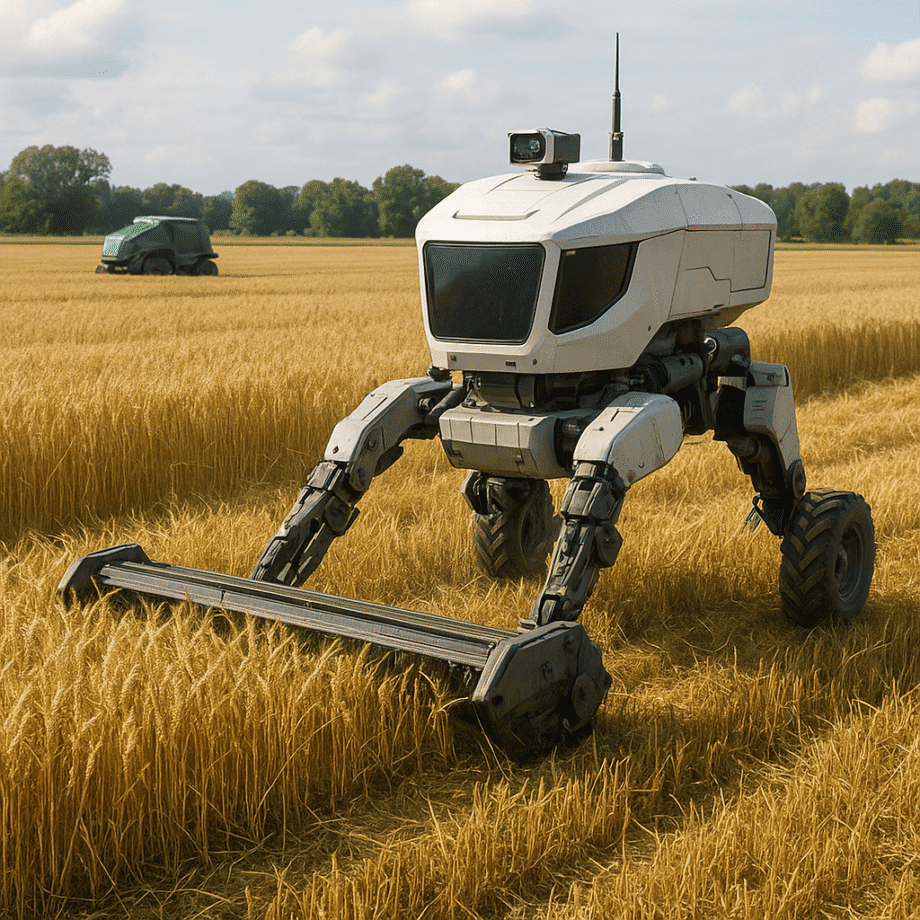

Recent years have seen a convergence of multiple high-tech domains within agricultural machinery. The integration of robotics, machine vision, and advanced navigation systems is redefining the way farmers approach routine tasks such as planting, weeding, and harvesting. Key components include:

- Sensors and Cameras: Multispectral and hyperspectral cameras capture detailed crop data, identifying stress, disease, and nutrient deficiencies at the leaf level.

- GNSS and RTK GPS: Real-time kinematic positioning provides centimeter-level accuracy for field operations, enabling precise guidance of tractors and harvesters.

- Edge Computing Units: On-board processors analyze sensor feeds instantly, making split-second decisions without relying on remote servers.

- Connectivity Platforms: 5G and Low-Power Wide-Area Networks (LPWAN) ensure constant data flow between machines, drones, and farm management systems.

These advancements converge to foster precision farming, where every square meter of land is treated according to its unique requirements. For example, a combine harvester equipped with real-time yield mapping can adjust its cutting height and fan speed on the fly, maximizing performance while minimizing waste. Similarly, weeding robots use machine learning algorithms to distinguish between crops and weeds, enabling targeted herbicide application that cuts chemical usage by up to 90%.

Economic Impact and Return on Investment

Investing in high-tech agricultural machinery represents a significant capital outlay for farm owners, but the potential returns are compelling. The key economic advantages include:

- Labor Savings: Autonomous machines can operate around the clock, reducing reliance on seasonal labor and mitigating workforce shortages.

- Resource Optimization: Variable-rate application technologies ensure that water, fertilizers, and pesticides are used only where needed, lowering input costs.

- Increased Throughput: Faster cycle times and minimal downtime translate into higher daily harvested acreage.

- Data-Driven Decisions: Historical performance data enables predictive maintenance, avoiding costly breakdowns during peak harvesting windows.

For mid-sized farms, the payback period for a network of harvesting robots and connected tractors can range from three to five years. Larger operations often achieve even faster returns due to economies of scale. Leasing models and pay-per-use agreements are also emerging, allowing smaller growers to access state-of-the-art equipment without full ownership. Ultimately, the adoption of automation not only elevates profitability but also provides a hedge against fluctuating commodity prices and labor market uncertainties.

Sustainability and Environmental Advantages

As agriculture faces the dual challenges of feeding a growing population and preserving natural resources, sustainable practices have moved to the forefront. Next-generation machinery contributes directly to ecological stewardship by:

- Reducing Soil Compaction: Autonomous machines are designed with lightweight materials and variable tire pressure systems, protecting soil structure and promoting root growth.

- Minimizing Chemical Runoff: Precision sprayers target individual plants, cutting pesticide and fertilizer runoff into waterways.

- Lowering Carbon Footprint: Electrified tractors and harvesters, combined with solar-charging stations, diminish dependency on diesel fuel.

- Enabling Cover Crop Integration: Robotics facilitate no-till planting and the incorporation of cover crops, leading to higher organic matter and improved water retention.

By leveraging sustainability-focused features, farmers can demonstrate compliance with environmental regulations, qualify for green subsidies, and appeal to eco-conscious consumers. Moreover, data collected by connected machines allows for lifecycle assessments, helping agribusinesses measure and minimize their overall ecological impact.

Challenges and Future Prospects

Despite the promise of integration and advanced capabilities, several hurdles must be addressed before AI-driven harvesting robots become ubiquitous:

- High Initial Costs: Even with leasing options, acquiring multiple autonomous units remains a financial barrier for smallholders.

- Infrastructure Requirements: Reliable broadband connectivity and on-farm charging stations are essential but not always available in rural regions.

- Regulatory Frameworks: Safety standards and liability rules for autonomous agricultural equipment are still evolving.

- Technological Standardization: Interoperability between hardware and software from different manufacturers requires open protocols and industry collaboration.

Looking ahead, research efforts are focused on enhancing machine intelligence, improving battery life, and developing modular attachments for diverse crop types. Pilot projects in orchards and vineyards are already demonstrating multi-arm robots capable of delicate fruit picking, reducing damage and improving yield consistency. Advances in swarm robotics might soon enable fleets of small robots to work together, offering cost-effective solutions for farmers with limited resources.

Embracing the Digital Transformation

The agricultural sector stands on the cusp of a digital revolution, with connected machinery, remote monitoring, and artificial intelligence converging to create a new era of farming. To fully harness these opportunities, stakeholders across the value chain—including equipment manufacturers, software developers, agronomists, and government agencies—must collaborate on standards, training programs, and data-sharing initiatives. As farms become more data-rich and machines grow more capable, the synergy between human expertise and machine precision will pave the way for resilient, productive, and environmentally responsible agriculture.