The integration of additive manufacturing into the agricultural sector is reshaping how farmers approach equipment maintenance, part production, and design innovation. By leveraging the capabilities of 3D printing, producers can achieve unprecedented levels of precision, customization, and sustainability. This article delves into the transformative potential of 3D printing in agricultural machinery, exploring its impact on design processes, supply chain dynamics, on-farm fabrication, and the broader technological landscape driving future growth.

Additive Manufacturing and Agricultural Innovation

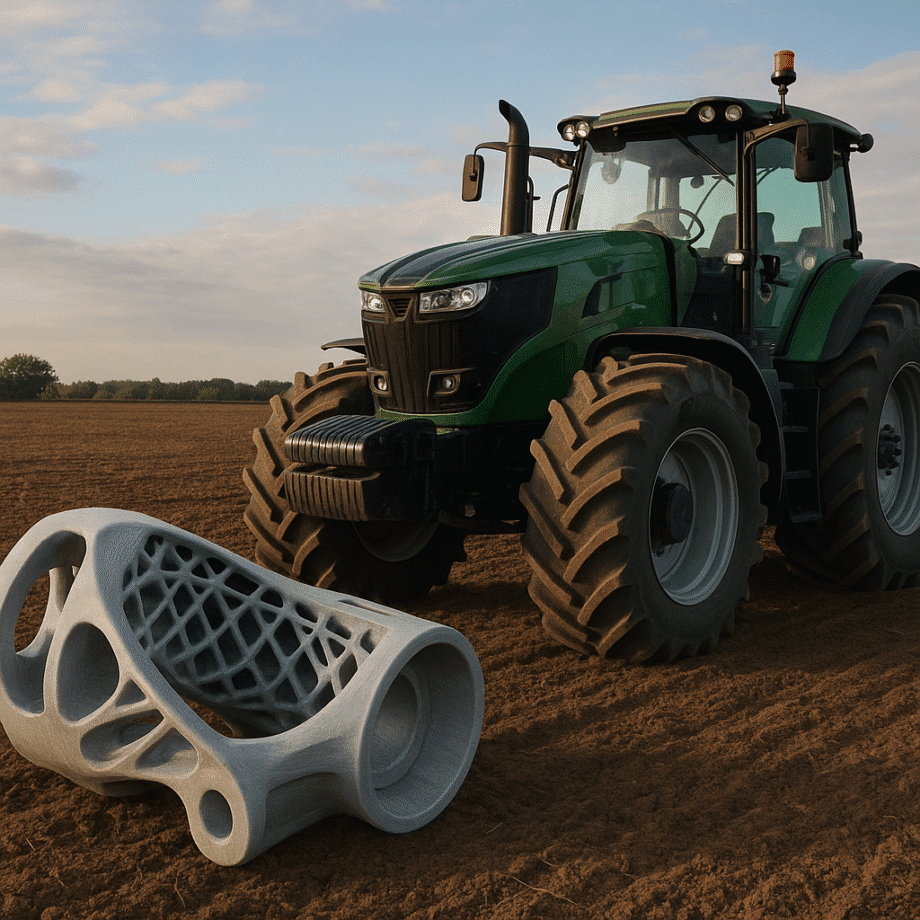

At its core, 3D printing—also known as additive manufacturing—builds objects layer by layer from digital models. In the context of agricultural machinery, this method offers a leap forward in design flexibility. Traditional manufacturing often relies on casting, machining, or molding, which can limit geometry and customization. With 3D printing, engineers can craft complex shapes such as lattice structures or internal fluid channels that reduce weight and improve performance, while maintaining robustness.

Key advantages include:

- Reduced lead times: Rapid prototyping enables fast iterations of new parts.

- On-demand production: Print critical spares when and where they are needed.

- Material efficiency: Additive processes generate less waste compared to subtractive machining.

- Functional integration: Combine several components into a single printed assembly.

These benefits translate into resilience for farm operations, minimizing downtime and ensuring equipment is always fit for purpose. For instance, custom nozzles for sprayers or intricate tractor gearbox components can be developed and printed in days rather than weeks.

Sustainable Production and Supply Chain Optimization

Traditional supply chains for agricultural machinery often involve long lead times, multiple suppliers, and significant transportation emissions. By adopting 3D printing, manufacturers and distributors can shift toward a more circular and agile model. Warehouses of digital part files replace physical inventories, allowing farmers and service centers to print parts on demand.

Environmental benefits are substantial:

- Lower carbon footprint: Reduced shipping and storage requirements.

- Energy savings: New machines optimized for efficiency and minimal waste.

- Recycled materials: Biodegradable polymers and recycled metals can be used in printers.

Moreover, the digital supply chain fosters greater transparency. Real-time monitoring of print jobs, coupled with blockchain-based traceability solutions, ensures that each component’s origin, material composition, and quality certifications are readily accessible. This bolsters trust in aftermarket parts and enhances regulatory compliance, especially in regions with strict agricultural equipment standards.

Custom Tools and On-Farm Fabrication

On-farm 3D printing stations empower farmers to become their own fabricators. From custom harvesting attachments to specialized seed planters, the ability to print tailored solutions on-site leads to performance gains and cost savings. Consider a scenario where a farmer encounters a broken sensor housing critical to an autonomous weeding robot. Instead of waiting weeks for a factory shipment, a replacement can be printed overnight.

Examples of on-farm applications:

- Prototyping new implement geometries adapted to local soil conditions.

- Printing jigs and fixtures for machine calibration and assembly.

- Fabricating ergonomic handles, brackets, or protective guards.

- Producing parts for drone-mounted sprayers or remote sensing devices.

These activities foster a culture of continuous improvement, where farmers and local workshops collaborate to refine designs and share digital blueprints. Online repositories and open-source platforms accelerate this process, offering downloadable files for everything from repair kits to fully integrated robotic platforms.

Challenges and Technological Advancements

Despite the promise of 3D printing, several hurdles remain before widespread adoption in agriculture:

- Material limitations: Not all metals or polymers used in heavy-duty machinery are printable at scale yet.

- Print speed: Large components can take many hours or days to fabricate.

- Quality assurance: Ensuring printed parts meet mechanical strength and fatigue requirements is critical.

- Initial investment: High-end industrial printers remain costly for small operations.

However, ongoing research and development are addressing these issues. Advances in multi-material printing enable the combination of metal, ceramic, and polymer layers, creating composites that rival traditional cast parts. High-speed sintering and directed energy deposition techniques are slashing print times, while in-situ monitoring systems employ machine vision and AI-driven analytics to guarantee part integrity.

Machine manufacturers are also adopting modular design philosophies, where standardized printed modules fit into existing platforms. This scalability reduces the barrier to entry for farms of all sizes. Training programs and cooperative models are being established to help farmers and technicians develop the skills needed to design, operate, and maintain 3D printing equipment.

In the coming years, the convergence of 3D printing with robotics, IoT sensors, and predictive analytics will usher in a new era of truly smart agricultural machinery—self-diagnosing, self-repairing, and optimized for maximal yield under varying field conditions. Such systems will not only increase productivity but also enhance the overall resilience of global food production networks.