Innovations in agriculture have transformed the way farmers manage fields, crops, and resources. Among these innovations, Variable Rate Technology (VRT) stands out as a pivotal tool in modern machinery, enabling growers to apply inputs more precisely and sustainably. By leveraging advanced sensors, mapping software, and automated controls, VRT empowers producers to make data-driven decisions that enhance productivity and reduce waste.

Understanding Variable Rate Technology

Definition and Core Principles

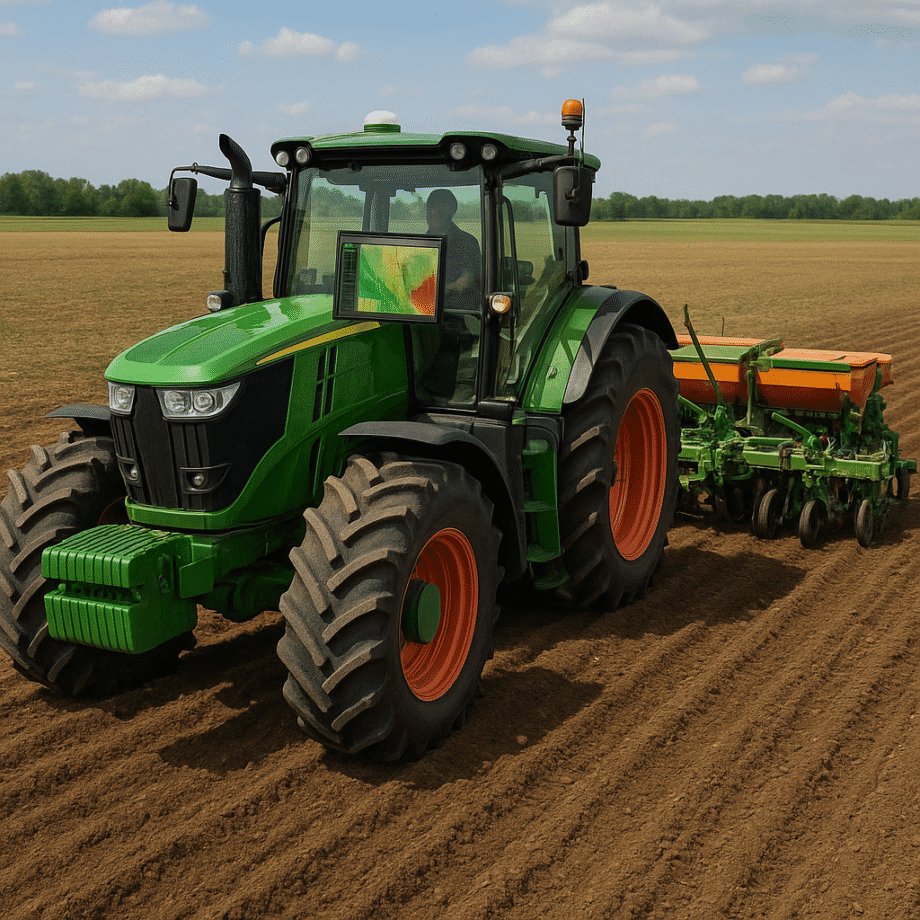

At its core, VRT allows equipment to modify the amount of inputs—such as seed, fertilizer, or chemicals—in real time as it moves across a field. This approach contrasts sharply with traditional uniform application, where each section of land receives the same treatment regardless of soil variability or crop needs. By harnessing GPS guidance and prescription maps, VRT systems interpret soil characteristics, moisture levels, and nutrient availability to tailor the application rate at every point.

Key Components

- GPS Receivers: Provide accurate positioning to align machinery movements with field maps.

- Variable Rate Controllers: Onboard computers that interpret prescription data and adjust output on the go.

- Flow Monitors and Sensors: Track real-time application rates, ensuring consistent performance.

- Prescription Maps: Digital field maps detailing variable application rates based on soil tests or yield history.

- User Interface Displays: Allow the operator to monitor metrics and override settings if necessary.

Practical Applications in Modern Farm Equipment

Seeders and Planters

Precision planting with VRT-enabled seeders optimizes yield potential by adjusting seeding rates according to soil fertility zones. High-fertility areas receive denser seeding, while marginal zones receive reduced rates to prevent overcrowding and resource competition. This targeted method helps farmers achieve uniform emergence and more efficient resource utilization.

Fertilizer Spreaders

Applying fertilizer at variable rates addresses nutrient deficiencies at a micro-scale, reducing overall input volumes and minimizing runoff. Modern spreaders equipped with VRT capabilities automatically modulate granule spread based on prescription data, ensuring that nitrogen, phosphorus, and potassium levels meet crop requirements without overapplication. Such precision contributes to both cost savings and environmental protection.

Sprayers and Irrigation Systems

Variable rate sprayers adjust chemical application—such as herbicides or pesticides—by detecting weed density or crop health indicators. Incorporating multispectral cameras and real-time analyzers, these sprayers can increase spray volume in infested areas and reduce it elsewhere, improving efficiency and reducing chemical exposure. Similarly, VRT-enabled irrigation systems distribute water variably across a field, delivering moisture where it’s most needed and conserving water in well-saturated zones.

Benefits for Farmers and the Environment

Economic Advantages

One of the most compelling reasons growers adopt VRT is the potential for significant cost savings. By precisely matching input levels to field conditions, farmers experience reduced expenditure on fertilizer, seed, and agrochemicals. In many cases, the return on investment for VRT equipment pays off within a few seasons through:

- Lower input costs due to targeted application

- Improved yield consistency across variable soil zones

- Reduced overlap and pass efficiency, saving fuel and labor hours

- Enhanced equipment utilization and longevity

Environmental Sustainability

As agricultural practices face growing scrutiny for their ecological footprint, VRT offers pathways to greater sustainability. By minimizing overapplication, farmers can curb nutrient leaching into waterways and reduce greenhouse gas emissions associated with fertilizer production. A shift to variable application also conserves resources such as water and energy, aligning production with environmental stewardship goals. Key environmental benefits include:

- Decreased nutrient runoff, protecting aquatic ecosystems

- Lower carbon footprint through reduced input manufacturing

- Enhanced soil health by avoiding hotspots of nutrient accumulation

- Optimized water usage, especially in drought-prone regions

Enhanced Decision-Making and Field Management

VRT systems collect comprehensive spatial data that serve as a foundation for continuous improvement. Farmers can analyze historical application patterns, relate them to yield maps, and refine future prescriptions. This iterative feedback loop fosters more accurate predictions and smarter allocation of resources each season. With the integration of machine learning and cloud-based analytics, equipment manufacturers are further elevating the capabilities of VRT, paving the way for fully automated, adaptive systems.

Future Outlook

Looking ahead, the fusion of robotics, artificial intelligence, and Variable Rate Technology promises to revolutionize farm operations. Autonomous tractors guided by VRT algorithms may soon manage entire fields, adjusting planting, fertilization, and spraying on the fly without human intervention. As connectivity improves and satellite data become more accessible, even small-scale producers stand to benefit from precision tools once reserved for large commercial operations.

Key Takeaways

- Variable Rate Technology fosters smart, site-specific management for precision agriculture.

- Real-time adjustments driven by data-driven insights optimize input use and boost efficiency.

- Significant cost savings and environmental gains stem from reduced waste and targeted application.

- Continuous data collection enhances strategic decisions, enabling ongoing field improvement.