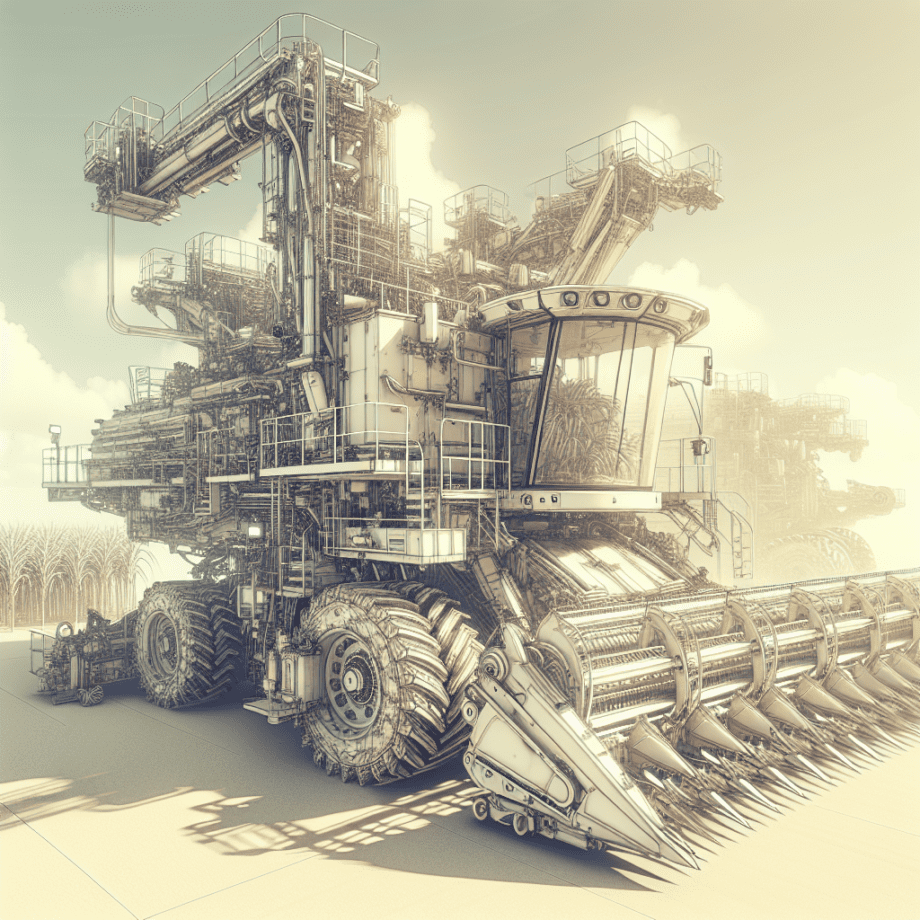

Sugarcane harvesting machinery plays a crucial role in the large-scale production of sugarcane, a vital crop for the global sugar industry. This article delves into the various types of machinery used in sugarcane harvesting, their technological advancements, and their impact on productivity and efficiency in the agricultural sector.

Types of Sugarcane Harvesting Machinery

The process of sugarcane harvesting has evolved significantly over the years, with the introduction of various types of machinery designed to enhance efficiency and reduce labor costs. The primary types of sugarcane harvesting machinery include whole-stalk harvesters, chopper harvesters, and billet harvesters. Each type has its unique features and benefits, catering to different farming needs and conditions.

Whole-Stalk Harvesters

Whole-stalk harvesters are designed to cut the entire sugarcane stalk at the base and lay it down in rows for further processing. These machines are particularly useful in regions where manual labor is still prevalent, as they allow for easier collection and transportation of the stalks. Whole-stalk harvesters are equipped with powerful cutting mechanisms and conveyors that ensure minimal damage to the cane, preserving its quality for subsequent processing.

Chopper Harvesters

Chopper harvesters, also known as chopper combines, are more advanced and widely used in large-scale sugarcane farming. These machines cut the cane into smaller pieces, known as billets, which are then collected and transported to the processing facility. Chopper harvesters are equipped with sophisticated cutting and cleaning systems that remove leaves and other impurities, ensuring that only the clean cane billets are collected. This type of harvester is highly efficient and can cover large areas in a relatively short period, making it ideal for extensive sugarcane plantations.

Billet Harvesters

Billet harvesters are similar to chopper harvesters but are specifically designed to produce uniform billets of sugarcane. These machines are equipped with precision cutting mechanisms that ensure consistent billet size, which is crucial for efficient processing and extraction of sugar. Billet harvesters are particularly popular in regions where sugarcane is processed into ethanol, as the uniform billets facilitate better fermentation and extraction processes.

Technological Advancements in Sugarcane Harvesting Machinery

The agricultural machinery industry has witnessed significant technological advancements in recent years, and sugarcane harvesting machinery is no exception. Modern harvesters are equipped with advanced features that enhance their performance, efficiency, and ease of use. Some of the key technological advancements in sugarcane harvesting machinery include GPS and precision farming technologies, automation and robotics, and improved cutting and cleaning systems.

GPS and Precision Farming Technologies

GPS and precision farming technologies have revolutionized the way sugarcane is harvested. Modern harvesters are equipped with GPS systems that enable precise navigation and mapping of the fields, ensuring optimal coverage and minimizing overlaps. Precision farming technologies also allow for real-time monitoring of the harvester’s performance, enabling farmers to make data-driven decisions and optimize their operations. These technologies not only enhance the efficiency of the harvesting process but also reduce fuel consumption and environmental impact.

Automation and Robotics

Automation and robotics have significantly improved the efficiency and productivity of sugarcane harvesting machinery. Modern harvesters are equipped with automated systems that control various aspects of the harvesting process, such as cutting, cleaning, and loading. These systems reduce the need for manual intervention, minimizing labor costs and human error. Additionally, robotic arms and sensors are increasingly being integrated into harvesters, enabling precise and efficient handling of the cane. Automation and robotics also enhance the safety of the harvesting process, reducing the risk of accidents and injuries.

Improved Cutting and Cleaning Systems

The cutting and cleaning systems of sugarcane harvesters have also seen significant improvements in recent years. Modern harvesters are equipped with advanced cutting mechanisms that ensure clean and precise cuts, minimizing damage to the cane and preserving its quality. The cleaning systems have also been enhanced to remove leaves, dirt, and other impurities more effectively, ensuring that only clean cane is collected. These improvements not only enhance the efficiency of the harvesting process but also improve the quality of the harvested cane, leading to better yields and higher profits for farmers.

Impact on Productivity and Efficiency

The introduction of advanced sugarcane harvesting machinery has had a profound impact on the productivity and efficiency of sugarcane farming. These machines have significantly reduced the time and labor required for harvesting, enabling farmers to cover larger areas and increase their yields. The improved cutting and cleaning systems have also enhanced the quality of the harvested cane, leading to better extraction rates and higher sugar content.

Moreover, the use of GPS and precision farming technologies has enabled farmers to optimize their operations, reducing fuel consumption and environmental impact. Automation and robotics have further enhanced the efficiency and safety of the harvesting process, minimizing labor costs and human error. Overall, the advancements in sugarcane harvesting machinery have transformed the industry, enabling farmers to achieve higher productivity and profitability.

Conclusion

Sugarcane harvesting machinery is essential for large-scale production, playing a crucial role in enhancing the efficiency and productivity of sugarcane farming. The various types of harvesters, including whole-stalk, chopper, and billet harvesters, cater to different farming needs and conditions. Technological advancements, such as GPS and precision farming technologies, automation and robotics, and improved cutting and cleaning systems, have further enhanced the performance and efficiency of these machines. As a result, sugarcane farmers can achieve higher yields, better quality cane, and increased profitability, contributing to the growth and sustainability of the global sugar industry.