Maintaining and cleaning diesel engines in agricultural machinery is crucial for ensuring consistent field performance and longevity of expensive equipment. This article explores key aspects of care, from identifying common engine components to applying advanced techniques that enhance overall reliability. Through practical guidance and detailed procedures, technicians and farm operators can keep tractors, combines, and other heavy-duty vehicles running at peak performance.

Common Agricultural Machinery and Their Diesel Engines

Overview of Key Equipment

Modern farms rely on a variety of diesel-powered machines designed to tackle tasks such as plowing, planting, harvesting, and baling. Notable examples include:

- Tractors: Versatile powerhouses used for towing implements and powering PTO-driven attachments.

- Combine Harvesters: Complex units that reap, thresh, and clean grain in a single pass.

- Seed Drills and Planters: Precision tools for sowing seeds at controlled depth and spacing.

- Balers: Equipment that compacts straw, hay, or crop residue into transportable bales.

Diesel Engine Fundamentals

Every piece of agricultural machinery features a robust diesel engine tailored for high torque at low RPM. Key elements include:

- Fuel Injection System: Precisely meters diesel to achieve efficient combustion.

- Air Intake and Filtration: Removes dust and debris common in field environments.

- Cooling Circuit: Uses coolant and radiator assemblies to maintain safe operating temperatures.

- Exhaust Aftertreatment: Reduces emissions of particulates and nitrogen oxides.

Best Practices for Diesel Engine Cleaning

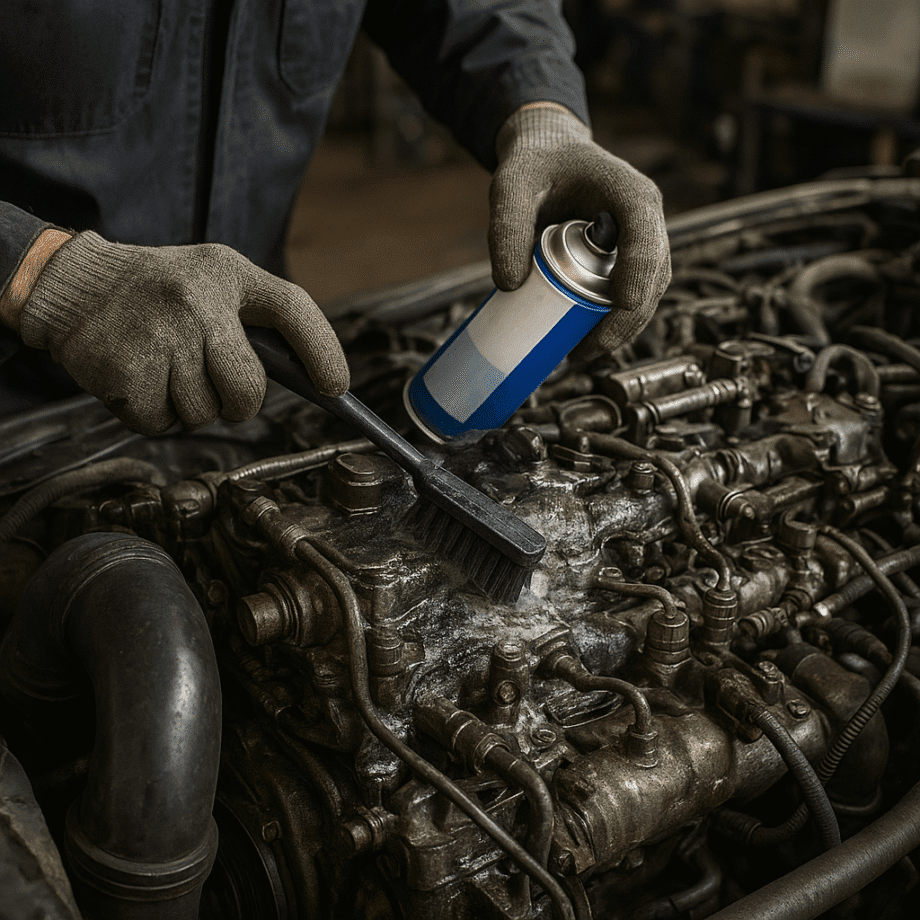

Exterior Cleaning Techniques

Cleaning the outside of an engine not only improves visual inspection but also prevents overheating and corrosion. Follow these steps:

- Disconnect the battery ground to prevent electrical hazards.

- Cover sensitive electrical connectors and air intake paths with plastic sheeting.

- Use a pressure washer on low to medium settings, keeping at least 30 cm distance.

- Apply biodegradable degreaser and scrub areas around valve covers and oil pans.

- Rinse thoroughly, ensuring no detergent residue clogs vents or fins.

Internal Component Cleaning

Over time, carbon deposits and sludge accumulate within piston crowns, cylinder walls, and intake valves. To address this:

- Use an approved engine cleaner or chemical additive that breaks down carbon.

- Run the engine at moderate RPM for the recommended time to circulate the cleaner.

- Perform an oil and filter change immediately afterward to remove dissolved contaminants.

Fuel System Flushing

Contaminated diesel can clog injectors and damage pump components. Key steps for cleaning include:

- Drain the fuel tank and refill with fresh, high-quality diesel.

- Install an in-line fuel system cleaner or injector flush solution.

- Run the engine under light load to allow the cleaner to dissolve varnish and sludge.

- Replace the fuel filter element and check for water separators.

Routine Maintenance for Optimal Performance

Scheduled Lubrication

Proper lubrication extends engine life by minimizing friction among moving parts. Follow the manufacturer’s intervals for:

- Engine Oil Changes: Use diesel-grade oils with the correct viscosity and additive package.

- Greasing Bearings: Apply high-pressure grease to chassis pivots, PTO shafts, and loader joints.

- Hydraulic Systems: Replace hydraulic oil and filters to protect pumps and valves.

Air and Oil Filter Replacement

Clogged filters restrict airflow and starve engines of clean lubrication. Ensure you:

- Check air cleaner service lights and perform dust bowl tests if available.

- Replace pre-cleaner elements and main filter cartridges when limits are reached.

- Swap oil filters at each oil change to trap particulates effectively.

Cooling System Inspection

Engines working in dusty or hot conditions risk overheating. Maintain the cooling circuit by:

- Flushing the radiator and heater cores annually.

- Checking coolant concentration and topping off with the correct mix of antifreeze.

- Inspecting hoses, clamps, and water pumps for leaks or wear.

Advanced Techniques and Troubleshooting

Injector Maintenance and Testing

Faulty injectors can lead to uneven combustion, smoke, and loss of power. To service them:

- Remove injectors and perform bench testing for spray pattern and opening pressure.

- Clean nozzles with ultrasonic baths or approved solvents.

- Replace injector seals and O-rings to prevent fuel leaks.

Compression Testing

Low compression readings often indicate worn rings or valves. The procedure involves:

- Removing all injectors and turning the engine over with a compression gauge installed.

- Comparing cylinder pressures against OEM specifications.

- Disassembling the top end if compression falls below acceptable thresholds.

Diagnosing Cooling and Overheating Issues

Frequent overheating demands a systematic approach:

- Verify thermostat operation and replace if sticking.

- Pressure-test the radiator cap and system to detect leaks.

- Inspect the fan clutch or electric fan circuits for proper engagement.

Ensuring Long-Term Reliability

Combining regular cleaning with proactive maintenance enhances fuel economy, reduces downtime, and safeguards investment in agricultural assets. By mastering both basic care and advanced diagnostic methods, you can maximize engine life and ensure smooth operation throughout demanding harvest seasons.