Agricultural machinery attachments play a pivotal role in enhancing the versatility and productivity of modern farming equipment. By ensuring proper balance and precise alignment, farmers can achieve higher efficiency, prolonged durability, and improved safety on the field. This article explores the fundamental concepts, tools, and best practices necessary to master the art of balancing and aligning attachments, whether you’re working with plows, mowers, seeders, or sprayers.

Understanding Machinery Attachments

Before diving into balancing and alignment techniques, it’s essential to familiarize yourself with the types of attachments commonly used in agriculture and their impact on overall machine performance.

Common Types of Attachments

- Plows and cultivators: Soil-tilling implements requiring consistent ground contact.

- Mowers and cutters: Blades and rotating arms that demand precise calibration for uniform cuts.

- Seeders and planters: Devices that deposit seeds at exact depths and intervals.

- Sprayers and spreaders: Hydraulic systems distributing chemicals or fertilizers evenly.

The Role of Balance and Alignment

Improper balance can lead to excessive vibration, accelerated wear on bearings or the spindle, and increased fuel consumption. Misalignment, on the other hand, may cause skewed furrows, uneven planting depths, and premature failure of mechanical linkages.

Tools and Techniques for Balancing

Balancing attachments involves redistributing weight so that the center of mass aligns with the axis of rotation. This process reduces dynamic loads and minimizes vibration-induced damage.

Essential Tools

- Dial indicators: Measure runout and radial imbalance.

- Static balancers: Platforms that show weight distribution in a stationary state.

- Dynamic balancers: Electronic devices that balance rotating parts while in motion.

- Calibration weights: Standardized masses for testing balance accuracy.

Step-by-Step Balancing Procedure

- Secure the attachment on a flat, stable surface.

- Mount the dial indicator near the rotating element.

- Rotate the attachment slowly by hand to detect runout.

- Record high and low points, then add or remove weight accordingly.

- Re-check with the indicator until variance falls within acceptable limits.

Key Considerations

- Always follow manufacturer torque specifications.

- Inspect for worn or bent components before balancing.

- Use high-quality calibration weights to ensure precision.

Alignment Procedures for Optimal Performance

Accurate alignment guarantees that attachments track correctly behind a tractor or combine, maintaining straight lines and uniform operations.

Types of Alignment

- Longitudinal: Adjusting front-to-back tilt relative to the tractor’s centerline.

- Lateral: Ensuring side-to-side levelness across the implement’s width.

- Height: Setting proper working depth to avoid uneven soil disturbance.

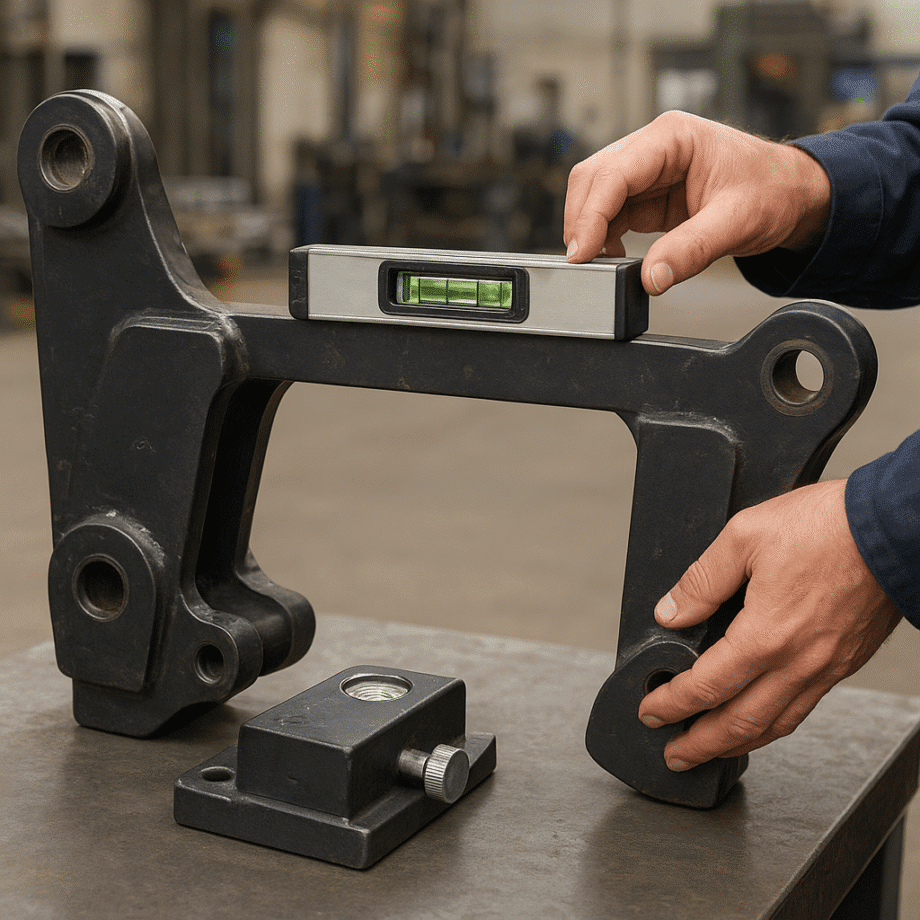

Alignment Tools and Instruments

- Laser levels: Offer high-visibility reference lines for both lateral and longitudinal alignment.

- Spirit levels: Simple but effective for small-scale adjustments.

- Measuring rods and gauges: Allow for precise height settings.

Alignment Workflow

- Park the tractor on level ground and engage the parking brake.

- Attach the implement and lower it to working height.

- Place laser or spirit level across critical reference points.

- Adjust hitch points, link arms, or mounting brackets to achieve level orientation.

- Verify that depth controls are set uniformly across all sections.

Best Practices and Safety Considerations

While technical proficiency is important, adherence to safety protocols and maintenance schedules is equally crucial to protect operators and extend machine life.

Maintenance Routines

- Daily inspections: Check for loose bolts, hydraulic leaks, and damaged hoses.

- Lubrication: Apply grease to pivot points and bearings to reduce friction.

- Component replacement: Swap out worn discs, blades, or tines to maintain performance.

Safety Guidelines

- Hydraulic lockout: Relieve pressure before disconnecting hoses.

- Locking pins and support stands: Prevent accidental lowering of heavy attachments.

- Personal protective equipment: Wear gloves, safety glasses, and steel-toed boots.

Enhancing Longevity

Implementing a systematic approach to balancing and alignment directly contributes to the long-term reliability of agricultural machinery. By minimizing unnecessary stresses, you safeguard critical components and optimize fuel utilization.

Improving Field Efficiency

When attachments are balanced and aligned correctly, tractor operators can cover more acres per hour with consistent results. This translates into reduced operational costs and higher crop yields, making precise attachment setup an indispensable aspect of modern farming.