The advent of automation has ushered in a transformative era for agricultural machinery, redefining harvest methods on farms of all scales. From the earliest mechanized plows to cutting-edge robotic harvesters, this progression has been fueled by relentless innovation in sensors, AIefficiency and ensure long-term sustainability.

Evolution of Agricultural Machinery

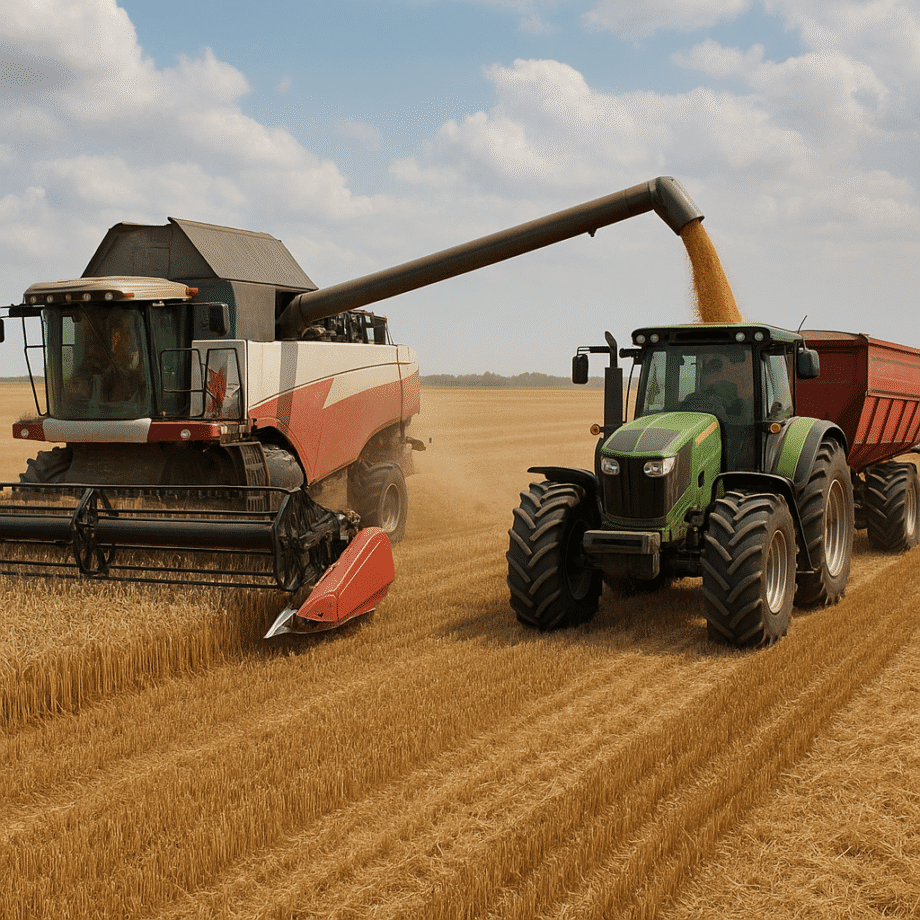

Mechanization in agriculture began in earnest during the Industrial Revolution, when steam-powered tractors replaced animal teams and manual labor. These early machines laid the foundation for later generations of equipment. The mid-20th century saw the advent of the modern tractor, combine harvester, and mechanical planters, each designed to manage a specific task more effectively than human workers.

Key milestones in this journey include:

- Introduction of the first gasoline-powered tractors in the 1910s

- Widespread adoption of the combine harvester in the 1930s

- Development of hydraulic systems that improved implement control in the 1950s

- Integration of basic electronics and GPS guidance in the 1990s

These innovations set the stage for today’s age of high-tech fields, where a single operator can manage hundreds of hectares with pinpoint accuracy.

Automation Technologies Transforming Harvesting

At the heart of modern harvesting solutions are robotics and advanced sensors. Robotic harvesters are equipped with vision systems and force-feedback arms that can identify, pick, and sort fruit and vegetables without human intervention. Simultaneously, unmanned aerial vehicles (UAVs) or drones offer aerial imagery to assess crop health and estimate yield before machines move in for the harvest. Underpinning these capabilities is a suite of technologies:

- Machine learning algorithms that classify ripeness and detect anomalies

- IoT connectivity to transmit real-time field data to cloud platforms

- GNSS and RTK GPS systems for sub-centimeter navigation

- Edge computing units that process images and sensor inputs on the go

By combining these elements, agricultural machinery can operate with minimal downtime and maintain consistent precision across diverse crop types.

Benefits of Automated Harvesting Systems

Integrating automation into the harvest process yields substantial gains:

- Increased Productivity: Machines work longer hours without fatigue, covering more ground per day.

- Labor Cost Reduction: Scarcity of skilled workers is mitigated by deploying autonomous units.

- Resource Optimization: Targeted application of water and fertilizers based on sensor data reduces waste.

- Data-Driven Decisions: Harvesters equipped with analytics modules generate insights for future planting and crop management.

- Enhanced Crop Quality: Gentle robotic arms minimize bruising and damage during picking.

These improvements not only boost yield but also enhance the overall resilience of farming operations against climate variability and market fluctuations.

Challenges and Future Directions

Despite rapid progress, several obstacles remain on the path to fully autonomous harvesting:

- High Upfront Costs: Advanced machinery can be prohibitive for small to medium-sized farms.

- Technical Complexity: Operating and maintaining robotic systems requires specialized training.

- Connectivity Gaps: Rural areas often lack robust network infrastructure for reliable data exchange.

- Regulatory Hurdles: Safety standards and certification processes vary across regions.

Looking ahead, research efforts are focused on developing modular attachments that retrofit existing tractors, democratizing access to automation. Furthermore, open-source platforms are emerging to foster collaboration among equipment manufacturers, software developers, and agronomists. Innovations in renewable energy integration—such as solar-powered field robots—promise to reduce the carbon footprint of large-scale harvesting.

Case Studies and Real-World Implementations

Numerous pilot programs worldwide illustrate the practical impact of automated harvesters:

- California Vineyards: Autonomous grape harvesters equipped with multispectral cameras have cut labor needs by 60% while improving cluster sorting accuracy.

- Dutch Greenhouses: Robotic tomato pickers navigate confined greenhouse aisles, achieving up to 80% picking reliability in complex canopy structures.

- Australian Cotton Farms: Self-driving combines integrated with yield-mapping software generate field-level reports that optimize next-season planting.

Each case highlights the importance of tailoring machinery to specific crops, environments, and operational scales. As these technologies mature, cross-pollination of ideas between geographic regions will accelerate further breakthroughs.

Conclusion

The integration of automation in large-scale harvesting represents a pivotal transformation in agriculture. By leveraging robotics, AI, and robust data-driven approaches, farms are achieving unprecedented levels of efficiency and productivity. While challenges around cost, training, and infrastructure remain, ongoing innovation promises to make automated systems more accessible and sustainable. The future of harvesting lies in the synergy between cutting-edge machinery and intelligent decision-making, ensuring global food security for decades to come.