Selecting the right seeder can transform planting operations, delivering higher yields and reducing labor costs. This guide explores key considerations when choosing a seeder for various crops, examines popular seeder technologies, and offers practical advice to optimize performance in the field. By understanding how equipment specifications and field conditions align with your planting goals, you can achieve more consistent stands and improved profitability.

Choosing Based on Crop Type and Field Conditions

Every crop has unique requirements: seed size, row configuration, and planting depth all influence the optimal choice of seeder. Before investing in machinery, evaluate your field’s soil texture, moisture, and topography. Proper alignment between equipment and environment ensures precision planting and reduces seed waste.

- Small Grains: Wheat, barley, and oats thrive when sown with a grain drill that delivers uniform depth and spacing. A press wheel or depth-control gauge helps maintain consistency on variable terrain.

- Row Crops: Corn, soybeans, and cotton demand row-crop planters equipped with individual seed meters. Look for adjustable row units to match specific spacing requirements and accommodate crop rotation.

- Cover Crops: Mixes of legumes and grasses often require broadcast or air seeders. These systems can handle larger volumes of seed and distribute them evenly over a wide area before incorporating the seeds into the soil.

- Vegetables and Specialty Crops: Precision vacuum planters or pneumatic seeders work best for delicate seeds such as carrots or onions, ensuring single-seed drop accuracy and minimal damage.

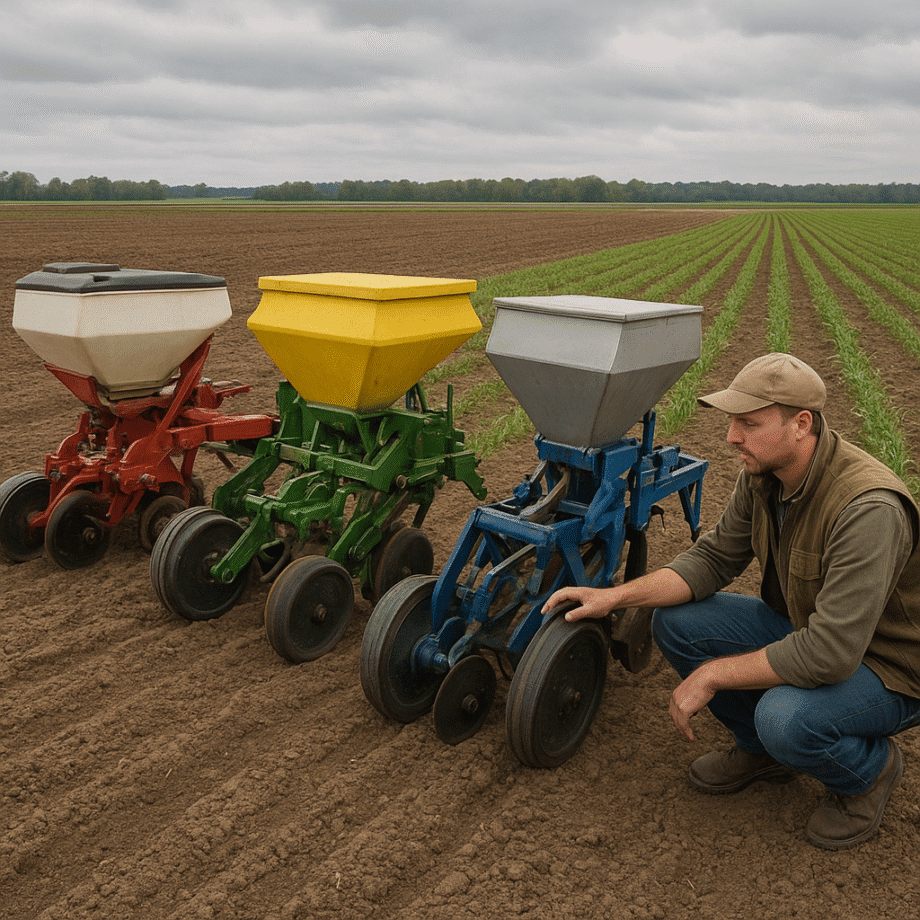

Comparing Seeder Technologies

Modern seeder models vary by seed-metering mechanism, power source, and hitch type. When weighing options, consider the balance between upfront investment and long-term gains in efficiency and yield potential.

Pneumatic and Air Seeder Systems

- Uses compressed air to transport seeds from a central hopper to coulters.

- Ideal for large-acreage farms seeking consistent seed delivery across wide working widths.

- Advanced models include variable-rate technology for on-the-fly adjustments.

Drill Seeders and Grain Drills

- Mechanical or pneumatic drive options available.

- Single or double-disc openers manage residue and cut through tough ground.

- Often equipped with press wheels to firm seed-to-soil contact.

Precision Planters

- Employ vacuum or finger-pickup meters for accurate singulation.

- Row-unit customization for various seed sizes and shapes.

- Hydraulically driven row markers for straight rows and better harvest efficiency.

Key Factors to Evaluate

- Calibration: Regular checks of meter calibration guarantee the correct population and reduce overlaps or skips.

- Versatility: Equipment capable of planting multiple crops and seed sizes prolongs machinery usefulness.

- Mechanization: Additional automation features—such as auto-reset depth control—save time and decrease operator fatigue.

- Maintenance: Ease of access to wear parts, greasing points, and meter components keeps downtime to a minimum.

- Sustainability: Low-disturbance openers preserve soil structure and moisture, supporting long-term farm health.

Implementing Maintenance and Best Practices

Even the most advanced seeder underperforms without diligent upkeep and proper field techniques. Establish a routine service schedule and train operators in key procedures.

- Inspect seed meters and brushes at the start of each season; replace worn paddles or plates.

- Clean hoppers and delivery tubes daily to prevent seed bridging and clogging.

- Check hitch settings and frame alignment to avoid uneven seed placement.

- Monitor tire pressure and gauge wheel tension to maintain consistent depth control.

- Use dry, treated seed to reduce moisture-related damage in metering systems.

Case Studies and Practical Tips

Farmers across diverse regions have achieved notable gains by matching seeder type to their specific farming conditions. Consider the following examples:

- A wheat producer in the Great Plains switched from a broadcast spreader to a precision grain drill. The result was a 12% boost in germination rates and significant fertilizer savings due to uniform seed depth.

- An organic vegetable grower adopted a vacuum seeder, enabling single-seed accuracy for carrot and leek planting. This method halved thinning labor and increased marketable yield by 18%.

- A mixed-crop operation invested in an air seeder with sectional control. By varying seeding rates across soil zones, they reduced seed costs by 20% and optimized stand density for higher profits.

Adjust seeder settings based on soil moisture and residue cover. When tackling heavy residue, slightly open the disc angle to improve trash flow. In lighter soils, lower downforce to prevent over-compaction. Keeping an eye on seeding depth and calibration logs ensures consistent field performance.