Grain dryers play a crucial role in ensuring the quality of post-harvest processing. These machines are essential for reducing the moisture content of grains to safe levels, thereby preventing spoilage and maintaining the nutritional value of the produce. This article delves into the importance of grain dryers, their types, and the technological advancements that have revolutionized their efficiency and effectiveness.

The Importance of Grain Dryers in Agriculture

Grain dryers are indispensable in modern agriculture due to their ability to preserve the quality and extend the shelf life of harvested grains. High moisture content in grains can lead to mold growth, insect infestation, and biochemical changes that degrade the quality of the produce. By reducing the moisture content to optimal levels, grain dryers help in maintaining the integrity and market value of the grains.

Preventing Spoilage and Loss

One of the primary functions of grain dryers is to prevent spoilage. Grains harvested with high moisture content are prone to microbial growth, which can lead to significant losses. Mold and fungi thrive in moist conditions, producing mycotoxins that are harmful to both humans and animals. By effectively drying the grains, these machines mitigate the risk of contamination and ensure that the produce remains safe for consumption.

Maintaining Nutritional Value

Grain dryers also play a vital role in preserving the nutritional value of the grains. Excess moisture can cause biochemical changes that degrade essential nutrients. For instance, high moisture levels can lead to the breakdown of proteins and vitamins, reducing the overall nutritional quality of the grains. By maintaining optimal moisture levels, grain dryers help in preserving the nutritional integrity of the produce.

Types of Grain Dryers

There are several types of grain dryers, each designed to meet specific needs and conditions. The choice of a grain dryer depends on factors such as the type of grain, the scale of operation, and the environmental conditions. The most common types of grain dryers include batch dryers, continuous flow dryers, and bin dryers.

Batch Dryers

Batch dryers are designed to dry a specific quantity of grain at a time. These dryers are suitable for small to medium-scale operations and are known for their simplicity and ease of use. The grains are loaded into the dryer, where they are exposed to heated air until the desired moisture content is achieved. Batch dryers are versatile and can be used for a variety of grains, making them a popular choice among small-scale farmers.

Continuous Flow Dryers

Continuous flow dryers are designed for large-scale operations and are capable of drying large quantities of grain continuously. These dryers consist of a series of drying chambers through which the grains pass in a continuous flow. The grains are exposed to heated air as they move through the chambers, gradually reducing their moisture content. Continuous flow dryers are highly efficient and are commonly used in commercial grain processing facilities.

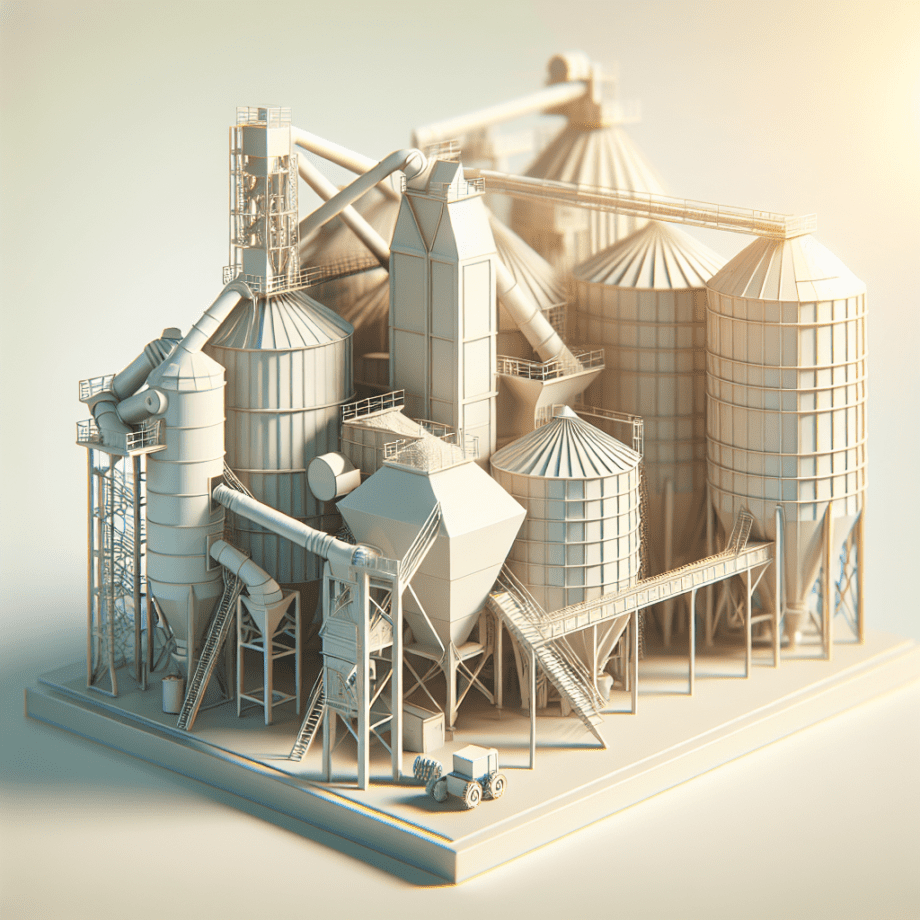

Bin Dryers

Bin dryers are designed to dry grains stored in bins or silos. These dryers use a combination of heated air and natural ventilation to reduce the moisture content of the grains. Bin dryers are suitable for long-term storage and are often used in conjunction with other drying methods to ensure that the grains remain dry and safe for extended periods. They are particularly useful in regions with high humidity, where natural drying methods may not be sufficient.

Technological Advancements in Grain Dryers

The field of grain drying has seen significant technological advancements in recent years. These innovations have improved the efficiency, effectiveness, and environmental sustainability of grain dryers. Some of the key advancements include the use of automation, advanced sensors, and energy-efficient technologies.

Automation and Control Systems

Modern grain dryers are equipped with advanced automation and control systems that allow for precise monitoring and control of the drying process. These systems use sensors to measure the moisture content of the grains and adjust the drying parameters accordingly. Automation not only improves the efficiency of the drying process but also reduces the risk of over-drying or under-drying, ensuring that the grains are dried to the optimal moisture content.

Energy-Efficient Technologies

Energy efficiency is a critical consideration in the design of modern grain dryers. Traditional drying methods can be energy-intensive, leading to high operational costs and environmental impact. Recent advancements have focused on developing energy-efficient technologies that reduce the energy consumption of grain dryers. These include the use of heat recovery systems, improved insulation, and the integration of renewable energy sources such as solar and biomass.

Advanced Sensors and Monitoring Systems

The use of advanced sensors and monitoring systems has revolutionized the field of grain drying. These sensors provide real-time data on the moisture content, temperature, and airflow within the dryer, allowing for precise control of the drying process. This not only improves the efficiency of the drying process but also ensures that the grains are dried uniformly, reducing the risk of spoilage and maintaining the quality of the produce.

Conclusion

Grain dryers are essential tools in modern agriculture, playing a crucial role in ensuring the quality and safety of post-harvest grains. By reducing the moisture content to optimal levels, these machines prevent spoilage, maintain nutritional value, and extend the shelf life of the produce. The choice of a grain dryer depends on various factors, including the type of grain, the scale of operation, and environmental conditions. Recent technological advancements have significantly improved the efficiency and effectiveness of grain dryers, making them more energy-efficient and environmentally sustainable. As the demand for high-quality grains continues to grow, the importance of grain dryers in agriculture will only increase, making them indispensable tools for farmers and commercial grain processors alike.