Weeding Machinery: Reducing Labor Costs and Increasing Efficiency

Weeding is a critical task in agriculture, essential for ensuring healthy crop growth and maximizing yields. Traditionally, weeding has been a labor-intensive process, requiring significant human effort and time. However, advancements in agricultural machinery have revolutionized this aspect of farming, offering solutions that reduce labor costs and increase efficiency. This article delves into the various types of weeding machinery available today and their impact on modern agriculture.

Types of Weeding Machinery

Weeding machinery comes in various forms, each designed to address specific needs and conditions in agricultural fields. The primary types include mechanical weeders, thermal weeders, and chemical weeders. Each type has its own set of advantages and limitations, making them suitable for different farming practices and crop types.

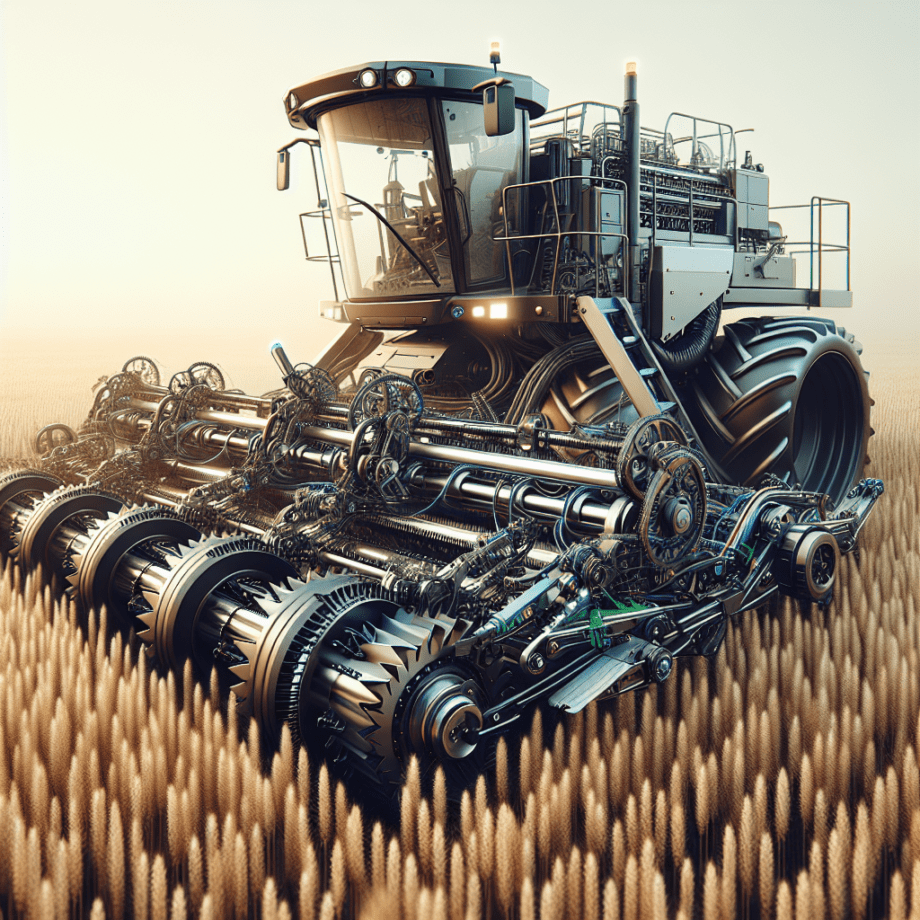

Mechanical Weeders

Mechanical weeders are among the most commonly used weeding machines. They operate by physically removing weeds from the soil, either by cutting, uprooting, or burying them. These machines can be further categorized into hand-pushed weeders, tractor-mounted weeders, and robotic weeders.

- Hand-Pushed Weeders: These are simple, manually operated tools that are ideal for small-scale farming or gardening. They are cost-effective and easy to use but require physical effort.

- Tractor-Mounted Weeders: These machines are attached to tractors and are suitable for larger fields. They offer higher efficiency and can cover more ground in less time compared to hand-pushed weeders.

- Robotic Weeders: The latest innovation in weeding technology, robotic weeders use sensors and artificial intelligence to identify and remove weeds autonomously. They are highly efficient and can operate continuously, reducing the need for human intervention.

Thermal Weeders

Thermal weeders use heat to kill weeds, either by flaming, steaming, or using hot water. These machines are particularly effective for organic farming, as they do not rely on chemicals. Thermal weeders can be used in various settings, from small gardens to large agricultural fields.

- Flame Weeders: These machines use propane burners to produce a flame that scorches the weeds, causing them to wilt and die. Flame weeders are effective for controlling annual weeds but may require multiple passes for perennial weeds.

- Steam Weeders: Steam weeders use high-temperature steam to kill weeds. They are effective for both annual and perennial weeds and can be used in various weather conditions.

- Hot Water Weeders: These machines use boiling water to kill weeds. They are environmentally friendly and can be used in sensitive areas where chemicals are not allowed.

Chemical Weeders

Chemical weeders, also known as herbicide applicators, use chemicals to kill or inhibit the growth of weeds. These machines can be highly effective but require careful handling to avoid damage to crops and the environment. Chemical weeders can be classified into sprayers, wipers, and injectors.

- Sprayers: Sprayers distribute herbicides over a wide area, making them suitable for large fields. They can be mounted on tractors or operated manually, depending on the scale of the operation.

- Wipers: Wipers apply herbicides directly to the weeds, minimizing the risk of damage to crops. They are ideal for spot treatment and can be used in conjunction with other weeding methods.

- Injectors: Injectors deliver herbicides directly into the soil, targeting the roots of the weeds. This method is effective for controlling deep-rooted weeds and reducing herbicide runoff.

Impact on Labor Costs and Efficiency

The adoption of weeding machinery has had a profound impact on labor costs and efficiency in agriculture. By automating the weeding process, these machines significantly reduce the need for manual labor, allowing farmers to allocate their resources more effectively. This section explores the various ways in which weeding machinery contributes to cost savings and increased productivity.

Reduction in Labor Costs

One of the most significant benefits of weeding machinery is the reduction in labor costs. Manual weeding is time-consuming and labor-intensive, often requiring a large workforce to manage extensive fields. By contrast, weeding machines can cover large areas quickly and efficiently, reducing the need for human labor. This not only lowers labor costs but also mitigates the challenges associated with labor shortages, particularly during peak farming seasons.

For example, a tractor-mounted weeder can cover several acres in a single day, a task that would take a team of workers several days to complete manually. Similarly, robotic weeders can operate continuously, even during nighttime, further enhancing productivity and reducing the reliance on human labor.

Increased Efficiency and Precision

Weeding machinery also enhances efficiency and precision in weed control. Traditional manual weeding methods are prone to human error, leading to inconsistent results and potential damage to crops. In contrast, modern weeding machines are equipped with advanced technologies such as GPS, sensors, and artificial intelligence, enabling them to identify and target weeds with high accuracy.

For instance, robotic weeders use machine vision to distinguish between crops and weeds, ensuring that only the unwanted plants are removed. This precision reduces the risk of crop damage and promotes healthier plant growth. Additionally, the use of GPS technology allows for precise navigation and coverage, ensuring that no areas are missed or treated multiple times.

Environmental Benefits

In addition to labor and efficiency gains, weeding machinery offers environmental benefits. Mechanical and thermal weeders, in particular, provide eco-friendly alternatives to chemical herbicides, reducing the reliance on potentially harmful chemicals. This is especially important in organic farming, where the use of synthetic herbicides is restricted.

Moreover, the precision of modern weeding machines minimizes the risk of herbicide runoff and soil contamination, promoting sustainable farming practices. By targeting weeds more effectively, these machines also reduce the need for repeated treatments, further decreasing the environmental impact.

Challenges and Future Prospects

While weeding machinery offers numerous advantages, it is not without challenges. The initial cost of purchasing and maintaining these machines can be high, particularly for small-scale farmers. Additionally, the complexity of some advanced machines may require specialized training and technical support.

Despite these challenges, the future prospects for weeding machinery are promising. Ongoing advancements in technology are likely to make these machines more affordable, user-friendly, and efficient. Innovations such as autonomous drones for aerial weeding and the integration of machine learning algorithms for improved weed detection are expected to further enhance the capabilities of weeding machinery.

In conclusion, weeding machinery plays a crucial role in modern agriculture, offering solutions that reduce labor costs and increase efficiency. By embracing these technologies, farmers can improve their productivity, promote sustainable practices, and ensure the health and vitality of their crops.