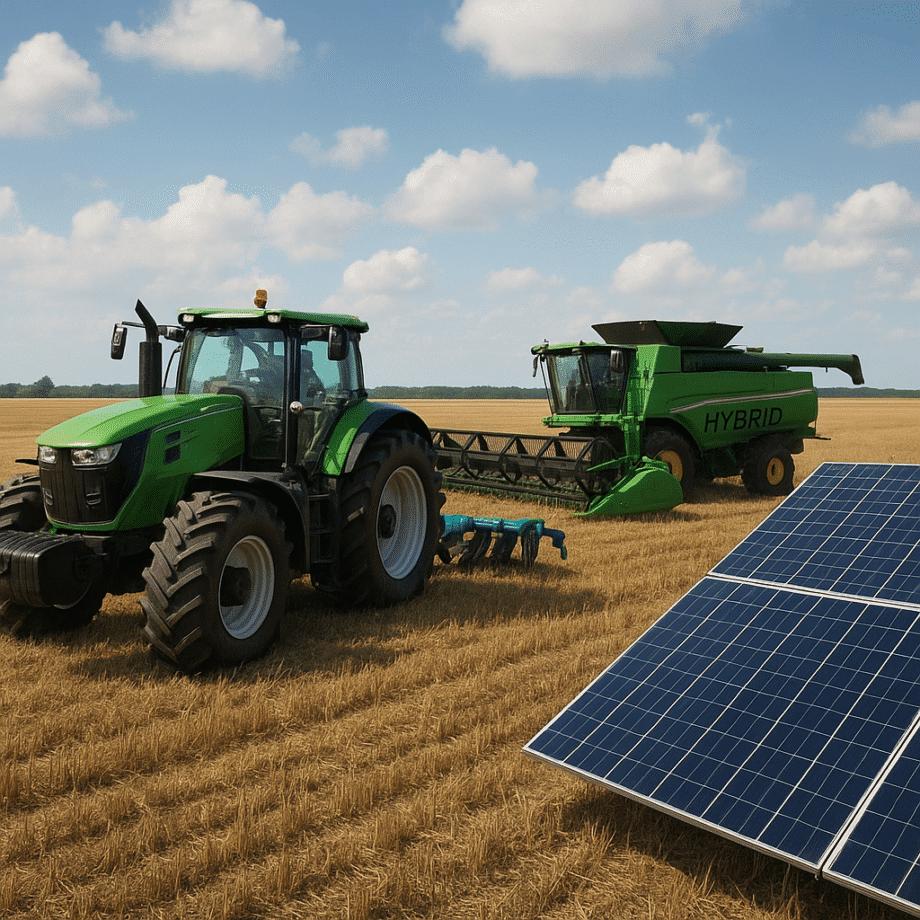

The rapid evolution of farm machinery is reshaping modern agriculture, as diesel engines increasingly combine with electric drives to create hybrid-powered equipment. This technological fusion aims to meet growing demands for higher efficiency, lower emissions, and improved operational flexibility. By leveraging advanced control systems and innovative energy sources, manufacturers are unlocking new capabilities in planting, tillage, and harvest operations.

Global Trends in Hybrid-Powered Agriculture

Across continents, farmers and equipment makers are embracing hybrid solutions to address the dual pressures of environmental regulation and rising fuel costs. The push toward renewable integration has accelerated collaborations between traditional tractor OEMs and electric drivetrain specialists. In regions where off-grid renewable power is abundant, hybrid tractors can recharge batteries on-site, reducing reliance on external refueling stations. Conversely, in large-scale grain operations, hybrid combines harness regenerative braking to store energy during field operation.

Key market drivers include:

- Stricter emissions standards prompting the adoption of sustainability-oriented machinery

- Volatile diesel prices encouraging improved fuel economy

- Advances in energy storage density enabling longer electric-only operation

- Government incentives for low-carbon agricultural equipment

The convergence of these factors is creating a favorable environment for hybrid farm equipment development, while farmer-entrepreneurs seek scalable, low-risk entry points into this emerging sector.

Innovations Driving Hybrid Farm Machinery

Recent breakthroughs in powertrain design and software controls are the backbone of next-generation hybrid tractors and implements. Manufacturers are experimenting with multiple hybrid architectures, such as series, parallel, and power-split systems, each offering unique advantages in specific field tasks.

- Power-Split Drivetrains: Combine mechanical and electrical power flows to optimize torque delivery during soil cultivation.

- Regenerative Braking: Captures kinetic energy during downhill or deceleration phases, storing it for later use.

- Bidirectional Charging: Allows implements to feed stored energy back into the grid or power ancillary equipment.

- Smart Sensors and IoT connectivity: Monitor engine load, battery state, and terrain conditions to dynamically allocate power.

- Data Analytics-based Controls: Predictive algorithms adjust hybrid operation modes for peak productivity under varying field conditions.

One promising approach leverages autonomy platforms, where hybrid power management algorithms communicate with onboard navigation systems, ensuring each component runs at its optimal efficiency point. This synergy reduces fuel consumption by up to 30% compared to conventional diesel tractors under similar workloads.

Environmental and Economic Impacts

By replacing portions of diesel usage with electric power, hybrid equipment significantly trims greenhouse gas output. Studies report CO₂ reductions of 20–40%, especially in tasks with frequent speed changes, such as row-crop planting or loader operations. Additionally, localized noise pollution decreases when machines operate in electric mode, enhancing working conditions in sensitive environments like livestock facilities.

On the economic front, farmers benefit from:

- Lower operational expenses due to reduced diesel consumption.

- Decreased maintenance costs, as electric motors have fewer moving parts than internal combustion engines.

- Extended equipment life through smoother torque delivery and less mechanical stress.

However, the initial capital investment remains a barrier. Hybrid tractors can cost 25–35% more upfront than their diesel-only counterparts. To alleviate this, manufacturers are exploring leasing models, pay-per-use schemes, and cooperative ownership structures. These approaches spread financial risk and align costs with actual machine utilization.

Obstacles and Technological Gaps

Despite swift progress, several challenges hinder widespread adoption of hybrid farm equipment. The weight and volume of current battery packs limit payload capacity and field endurance. Ongoing research into high-energy-density cells and lightweight materials aims to overcome this limitation, yet large-scale deployment is still years away.

Other hurdles include:

- Inadequate charging infrastructure in rural areas, complicating on-farm recharging cycles.

- Complex maintenance requirements for dual-power systems, necessitating specialized technician training.

- Integration issues between legacy implements and new hybrid power units, leading to compatibility constraints.

To address these obstacles, collaborative efforts between OEMs, battery suppliers, and farmers are crucial. Field trials in diverse agroecosystems help refine hybrid systems and surface unanticipated issues, enabling iterative design improvements.

Future Outlook and Adoption Strategies

Looking ahead, the agricultural sector is poised to embrace a holistic approach to farm energy management. Hybrid-powered equipment will integrate with precision agriculture platforms, renewable microgrids, and on-farm storage assets, forming a resilient, decentralized power network. In this vision, tractors and harvesters not only perform mechanical tasks but also function as mobile energy management nodes, balancing supply and demand across the farmstead.

Successful adoption strategies include:

- Phased implementation, starting with hybrid auxiliary systems before full powertrain conversion.

- Training programs focused on adaptability and best practices for hybrid maintenance.

- Partnerships with energy providers to establish shared electrification infrastructure in rural communities.

- Public–private funding initiatives to drive research into advanced power electronics and resilience-enhancing design features.

Ultimately, hybrid-powered farm equipment represents a transitional technology bridging traditional diesel machinery and future all-electric or hydrogen-based platforms. By combining the reliability of combustion engines with the environmental benefits of electric drives, farmers can chart a sustainable path forward—ensuring global food production remains both efficient and eco-friendly.