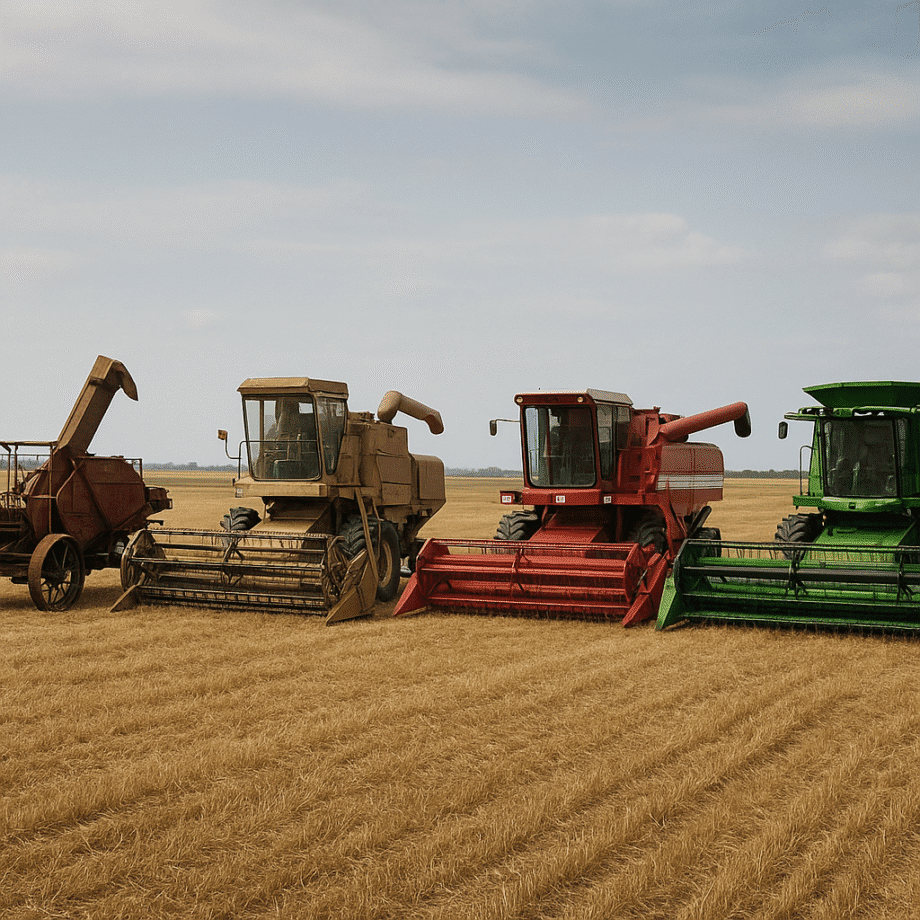

The evolution of agricultural machinery reflects a relentless drive toward greater efficiency and productivity. One of the most transformative machines in this journey is the combine harvester, a marvel of engineering that has reshaped the way grain crops are harvested. From humble beginnings in horse-drawn implements to today’s self-propelled giants equipped with satellites and sensors, combine harvesters embody decades of innovation that continue to influence global food production.

Origins of the Combine Harvester

Early farmers relied on manual labor and simple tools like scythes and flails to cut and thresh cereal grains. These separate operations were time-consuming and labor-intensive, making large-scale cultivation a formidable challenge. During the early 19th century, inventors sought to merge reaping and threshing into a single operation, sparking the first ideas for a combined machine.

In the 1830s, pioneers such as Hiram Moore in the United States and members of the Case family experimented with contraptions pulled by horses or oxen. These prototypes featured rotating cylinders to beat the cut stalks and winnowing fans to separate chaff from grain. Although cumbersome and prone to breakdowns, they proved the concept could dramatically reduce harvest time.

By mid-century, manufacturers began refining the design with stronger frames, improved cutting bars, and better threshing mechanisms. Steam power entered the picture, allowing early steam-driven combines to handle larger fields with greater consistency. Farmers embraced these early machines despite high costs, recognizing the long-term benefits of mechanized harvesting over manual methods.

As production techniques advanced, some combines incorporated adjustable sieves and variable speeds for different grain types. These early innovations laid the groundwork for modern harvesters, demonstrating how the fusion of mechanical reaping and threshing could revolutionize agriculture. The push for greater capacity and reliability ushered in an era of continuous improvement.

Technological Breakthroughs in the 20th Century

The arrival of the internal combustion engine transformed combine harvesters in the early 1900s. Diesel and gasoline engines provided more power at lower operating costs compared to steam. This shift enabled manufacturers to design self-propelled machines, freeing farmers from the need for separate tractors to tow implements across fields.

Hydraulic systems soon followed, offering precise control over cutting height, reel speed, and grain tank unloading. These upgrades enhanced adaptability across varying crop conditions. Farmers could make on-the-fly adjustments without tools, improving overall performance during unpredictable harvest windows.

Cab design also evolved to prioritize operator comfort and safety. Enclosed, climate-controlled cabins reduced fatigue during long hours in the field. Ergonomic controls, clear sightlines, and mounting platforms for communication equipment became standard, reflecting an increased focus on human factors engineering.

Mass production techniques and standardization lowered costs and improved parts availability. As components became more interchangeable, downtime decreased and maintenance became more straightforward. The emphasis on durability and ease of service established modern expectations for machine durability and uptime.

Modern Advances in Precision Farming

Today’s combine harvesters are integral to precision agriculture, leveraging satellite guidance, real-time monitoring, and advanced algorithms. GPS-based auto-steer systems maintain straight paths with centimeter accuracy, reducing overlap and minimizing soil compaction. This degree of precision maximizes field coverage and optimizes resource use.

Sensors fitted to modern combines measure moisture content, grain losses, and throughput rates on the go. Data is processed instantly, enabling farmers to adjust settings for optimal performance. Yield mapping generates detailed field reports, illustrating productivity variations across different sections of a plot.

Telematics and remote diagnostics connect machines to cloud platforms, allowing equipment managers to track fuel consumption, maintenance alerts, and operating hours from anywhere. This networked approach to machinery management enhances both connectivity and decision-making speed, reducing downtime and improving overall farm economics.

- Automated steering with RTK GPS

- Variable-rate yield monitoring

- Onboard grain quality analysis

- Residue management and chaff spreading

- Remote software updates and diagnostics

Integrating these technologies results in unparalleled automation and consistent harvesting operations. Modern combines adapt to varying crop conditions almost autonomously, ensuring each pass through the field delivers peak efficiency.

Emerging Trends and Future Directions

As agriculture moves toward a low-carbon future, electrification of field machinery is gaining traction. Prototype electric combines promise lower emissions and quieter operation, especially useful in environmentally sensitive regions. Advances in battery technology may soon allow these machines to match the endurance of diesel-powered units.

Artificial intelligence and machine learning algorithms are poised to further refine harvesting processes. Autonomous combines capable of making real-time adjustments to cutting height, threshing intensity, and grain cleaning could become commonplace. These systems will rely on cameras and LIDAR sensors to navigate fields and detect crop anomalies.

Environmental concerns are driving new standards for crop residue handling, soil compaction reduction, and water conservation. Companies are developing attachments and sustainable harvesting workflows that minimize negative impacts. This focus on sustainability aligns with global efforts to secure food supply while preserving natural resources.

Future machines will likely leverage modular designs, allowing farmers to customize configurations for specific crops and regional conditions. Enhanced data integration will link harvest results directly to farm management software, streamlining planning and logistics. These innovations aim to maximize yield, cut operational costs, and redefine the role of machinery in modern agriculture.