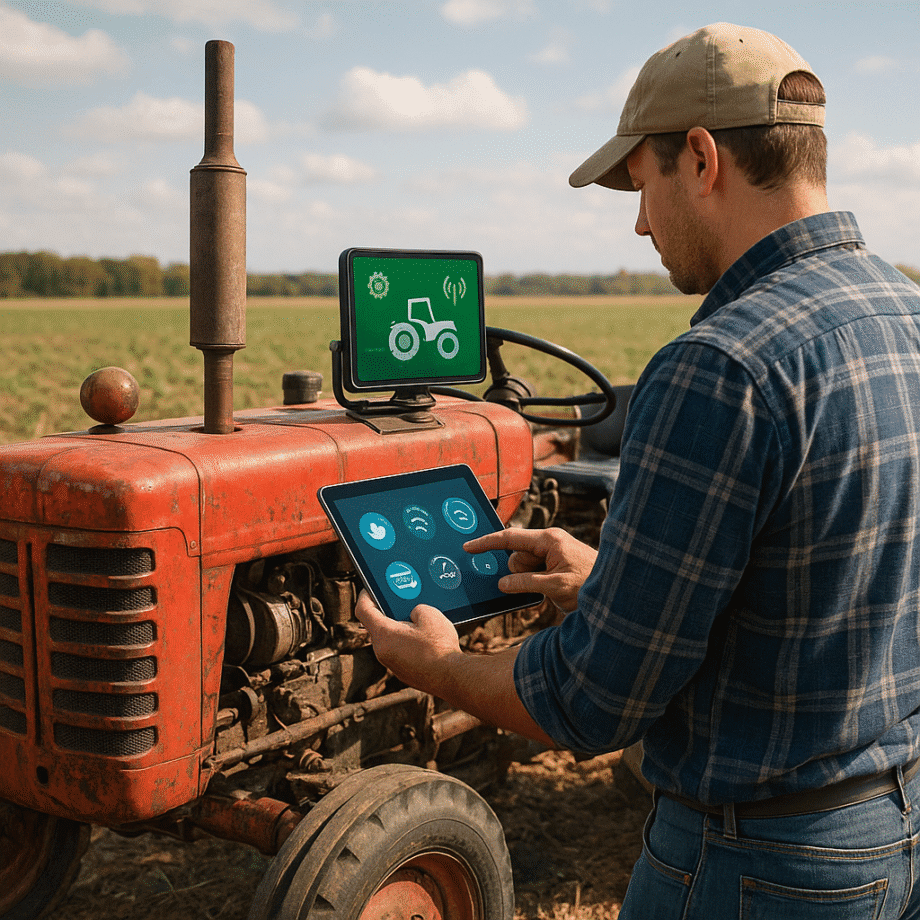

Upgrading a fleet of legacy tractors can breathe new life into older machinery, allowing farmers to leverage cutting-edge solutions without investing in entirely new equipment. By integrating digital tools and advanced sensors, agricultural professionals can optimize field operations, reduce downtime, and enhance overall productivity. This article explores the process of retrofitting older tractors with smart technologies, highlights the core components required for successful upgrades, and outlines practical strategies for seamless implementation.

Introduction to Smart Retrofit Solutions

Many farms rely on aging tractors that lack modern interfaces, automated controls, or real-time monitoring capabilities. Retrofitting these vehicles introduces a variety of benefits:

- Improved efficiency through precise fuel management and load balancing.

- Enhanced performance by adding electronic control units to optimize engine parameters.

- Streamlined maintenance with predictive analytics to schedule service before critical failures.

- Better resource allocation via data collection, enabling more informed decision-making.

Before diving into specific technologies, it’s crucial to assess the tractor’s existing condition. Evaluate mechanical wear, electrical system compatibility, and operator interface limitations. Conducting a thorough baseline inspection creates a roadmap for necessary upgrades and helps prioritize investments according to return on investment (ROI).

Key Technologies for Upgrading Older Tractors

Integrating smart tech into farm machinery involves several core components. Each element plays a vital role in transforming traditional tractors into connected, automated workhorses.

GPS Guidance and Auto Steering

- High-precision precision GPS receivers can achieve centimeter-level accuracy, reducing overlap and ensuring consistent coverage.

- Auto-steering kits mount onto existing hydraulic or electrical systems, enabling hands-free operation across long passes.

On-Board Sensors and Telematics

- Pressure, temperature, and vibration sensors gather real-time insights into engine health and implement performance.

- Telemetry modules transmit key metrics wirelessly to a centralized platform, allowing remote monitoring of fuel consumption, RPM, and hydraulic pressure.

Internet of Things ( IoT ) Connectivity

Equipping tractors with IoT gateways and cellular modems opens the door to cloud-based dashboards. This constant connectivity enables:

- Live tracking of machine location and operating status.

- Software updates that introduce new features or security patches over the air.

- Integration with farm management systems to correlate machine data with yield maps and agronomic information.

Automated Implement Control

- Hydraulic or electric actuators controlled by an electronic control unit (ECU) allow for precise depth, lift, and angle adjustments on planters, seeders, and sprayers.

- Advanced algorithms support variable rate application, matching fertilizer, pesticide, or seed density to field variability, thus maximizing yield potential and minimizing waste.

Implementation Strategies and Best Practices

While the potential benefits of retrofitting are substantial, successful integration depends on careful planning and execution. Below are key steps to follow:

1. Conduct a Comprehensive Needs Assessment

Begin by defining operational goals: Do you need to reduce input costs, improve coverage accuracy, or extend machine life? Align the retrofit plan with these objectives and rank upgrades by expected impact on farm productivity.

2. Partner with Experienced Integrators

Working alongside specialists who understand both legacy equipment and modern controls streamlines the installation process. Certified installers can handle wiring harness modifications, ECU programming, and system calibration more efficiently than in-house teams without prior experience.

3. Standardize Components Across the Fleet

Select retrofit kits and sensors from a limited set of manufacturers to ensure compatibility, simplify troubleshooting, and reduce spare parts inventory. Standardization also accelerates technician training and maintenance routines.

4. Develop a Training Program for Operators

New interfaces and automation features require operator familiarization. Create hands-on workshops to demonstrate GPS guidance, remote monitoring apps, and ECU dashboards. Empowering the crew with digital skills maximizes the value of each technology investment.

5. Monitor Performance and Iterate

After deployment, establish key performance indicators (KPIs) such as fuel savings, acreage covered per hour, and downtime reduction. Regularly review these metrics to validate ROI and identify further enhancements.

Case Studies in Tractor Modernization

Farmers around the globe have successfully upgraded their aging tractors, achieving remarkable gains in productivity and cost savings:

- A Midwest grain operation added a yield mapping module and automation kit to a 1998 tractor, resulting in a 12% reduction in seed overlap and 8% fuel savings.

- An Australian vineyard retrofitted several tractors with environmental sensors to monitor humidity and soil moisture, enabling precision irrigation that cut water usage by 20%.

- A Canadian dairy farm integrated telematics and predictive diagnostics, slashing unscheduled downtime by 30% and extending the average service interval by 25%.

These examples illustrate how a thoughtful combination of retrofits and digital tools can transform even the most venerable machines into indispensable assets in modern agriculture.