Selecting the ideal equipment for modern fields requires a deep understanding of both hydraulic systems and mechanical systems. Farmers and agribusiness professionals must evaluate factors such as efficiency, precision, cost-effectiveness, and durability before making investments. This exploration delves into core principles, direct comparisons, essential decision criteria, and emerging innovation driving the future of agricultural machinery.

System Fundamentals: Understanding the Basics

The Role of Hydraulic Systems

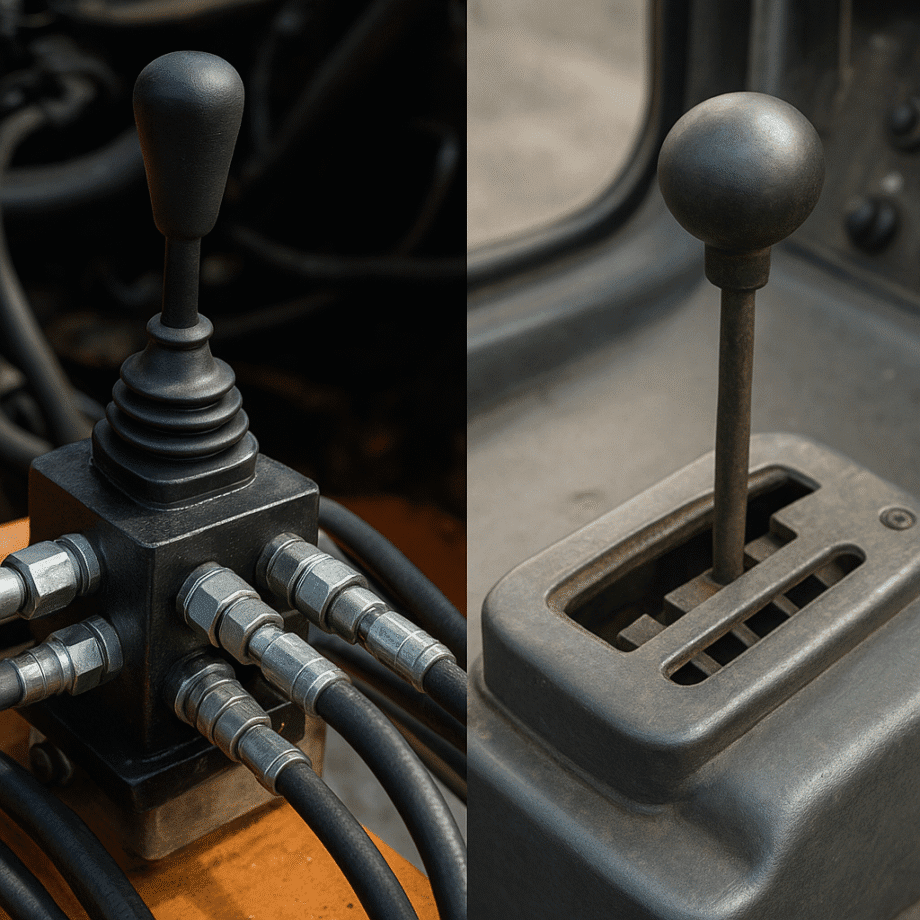

Hydraulic systems utilize fluid power to transmit force and motion. Key components include hydraulic pumps, valves, cylinders, and hoses. When pressurized oil moves through the circuit, it can lift heavy loads, operate attachments, or control steering mechanisms with remarkable performance. Advantages of hydraulics encompass:

- High power density, enabling lifting or pulling of large implements.

- Smooth, variable control, ideal for applications requiring fine precision.

- Compact design, reducing overall machine weight.

The Mechanics Behind Mechanical Systems

Mechanical systems rely on gears, shafts, belts, and mechanical linkages to transmit torque and motion. These setups are often simpler in design and operate through direct contact between solid components. Key features include:

- Robust construction, often yielding lower maintenance requirements in certain contexts.

- Predictable behavior in repetitive tasks thanks to fixed gear ratios.

- Cost-effective manufacturing and repairs due to widespread availability of parts.

Comparing Hydraulic and Mechanical Solutions

Power and Force Transmission

Hydraulics excel when it comes to exerting variable forces over a wide range. A single pump can power multiple actuators at different pressures, allowing one unit to handle several functions. Mechanical drive trains typically deliver constant torque based on gear ratios, making them well-suited for tasks where forces remain steady.

Control and Responsiveness

Variable flow rates in hydraulic circuits enable operators to adjust speed and force on the fly. This level of adaptability supports operations such as precision planting or variable-rate fertilization. Conversely, mechanical systems provide immediate mechanical linkage feedback and can be simpler to troubleshoot in the field when something goes awry.

Serviceability and Lifecycle Costs

Fluid contamination or seal wear in hydraulics demands periodic inspection and fluid changes to maintain reliability. However, mechanical systems face challenges like gear wear, chain stretch, or belt slipping, necessitating tension adjustments and occasional part replacements. Overall lifecycle costs depend on usage patterns, environmental conditions, and operator skill.

Key Criteria for Equipment Selection

Assessing Field Requirements

Before choosing a system type, outline the specific tasks you need the machine to perform:

- Load requirements (lifting, pulling, pressing).

- Speed and control finesse for tasks like precision seeding.

- Soil compaction constraints and ground engagement forces.

Budget and Total Cost of Ownership

Initial purchase price is only one component. Factor in:

- Replacement part costs and availability.

- Routine maintenance downtime.

- Fuel or energy consumption tied to system efficiency.

Environmental and Regulatory Compliance

Hydraulic fluids must meet eco-friendly standards to prevent contamination. Mechanical systems, while avoiding fluid spills, may still require lubricants subject to environmental regulations. Evaluating local guidelines ensures compliance and minimizes potential liabilities.

Operator Skills and Training

Trained personnel can maximize the benefits of advanced hydraulics, particularly when calibrating variable-rate implements or troubleshooting pressure issues. For straightforward operations, mechanical setups may reduce training time and complexity.

Emerging Trends and Future Prospects

Integration of Electronics and Control Systems

The next generation of tractors and implements features integrated sensors, electronic valves, and programmable controllers. These smart components enhance precision agriculture by optimizing flow rates, adjusting gear ratios on the move, and performing real-time diagnostics to prevent downtime.

Additive Manufacturing and Customized Parts

3D printing of bespoke components is revolutionizing spare part availability. From specialized hydraulic manifold blocks to tailor-made gears, farms can now source and print parts on demand, reducing lead times and boosting cost-effectiveness.

Alternative Power Sources

Electro-hydraulic hybrids and fully electric drivelines are emerging to reduce reliance on traditional diesel engines. These systems promise lower emissions, quieter operation, and enhanced efficiency, reshaping the landscape of agricultural machinery.

Sustainability and Circular Economy

Manufacturers are exploring recyclable materials for hoses, hoses with biodegradable fluids, and modular designs that simplify end-of-life recycling. Embracing this philosophy extends the durability of equipment and aligns with global sustainability goals.